FAES-PWR ESTECH AG: The Precise

FAES-PWR ESTECH AG was integrated into the ESTECH Group in two phases: Take-over of the former company PWR Präzisions-Werkzeuge AG in Rüti (ZH) in 2010 and of FAES AG in Wollerau (SZ) in 2016. Both companies joined to resolve questions of succession.

The companies, merged to form FAES-PWR ESTECH AG, were consolidated at the location in Rüti (ZH) in 2017.

The long-term market activities of both companies, their combined know-how and the increased size of the machine pool, complement each other ideally. PWR Präzisions-Werkzeuge AG was well established as a precision producer of individual parts, small lot series and demanding parts for machine tools, while FAES focussed on precision products in the mass-production sector.

Today, their combined competency allows them to offer precision parts in quantities ranging from one to several thousand. Customers include the aviation & space branch, automated laboratory equipment sector, precision equipment manufacturers, motor vehicle and machine production.

FAES-PWR ESTECH AG moved into its new production and office premises in the Joweid Centre in Rüti on 1 April 2022. The Joweid Centre is the former site of Sulzer Textil AG. The site has excellent transport links (S-Bahn and bus services within walking distance, 2 motorway junctions and half an hour to Zurich airport).

FAES-PWR ESTECH AG benefits from an excellent infrastructure at the new location and offers the optimal conditions for the further development of FAES-PWR ESTECH AG into a sustainable, service-oriented service provider for precision parts, components and assemblies.

The entire production can be arranged on a ground level area, with optimal production and order processes. The order centre and programming are located directly in the production hall.

PRECISION PRODUCTION

FAES-PWR ESTECH AG

Joweid-Zentrum 2

CH-8630 Rüti

Core know-how

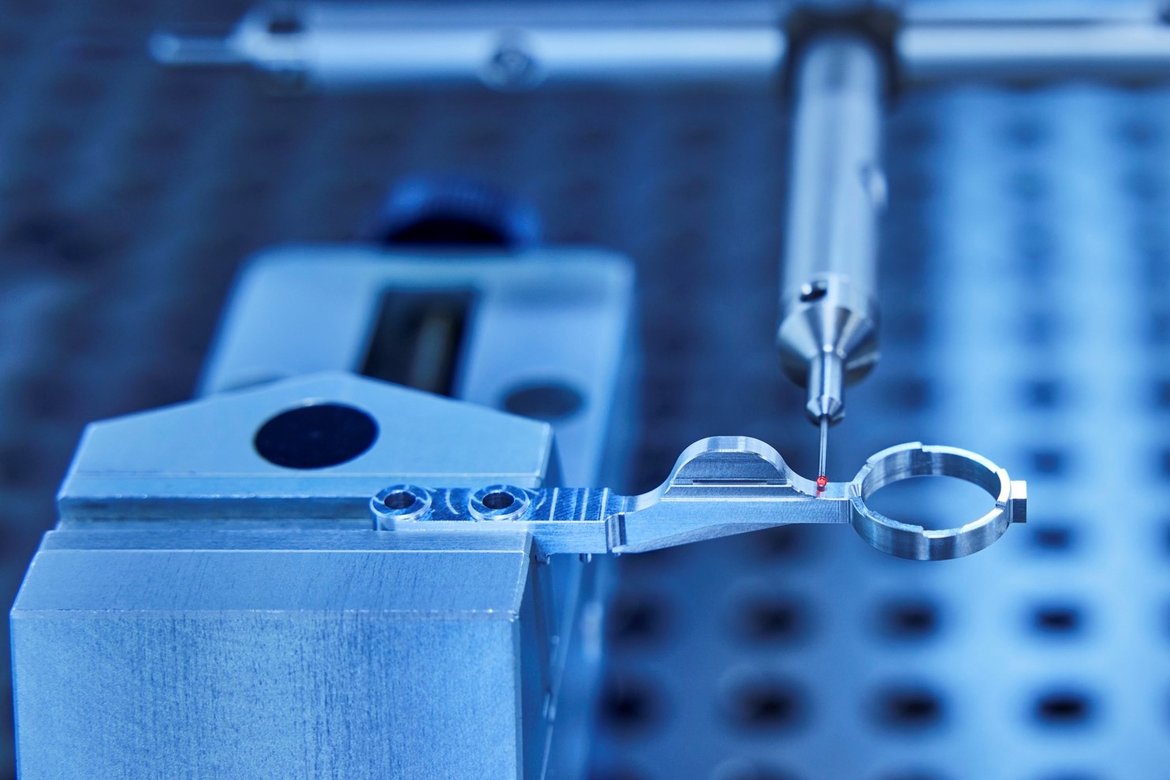

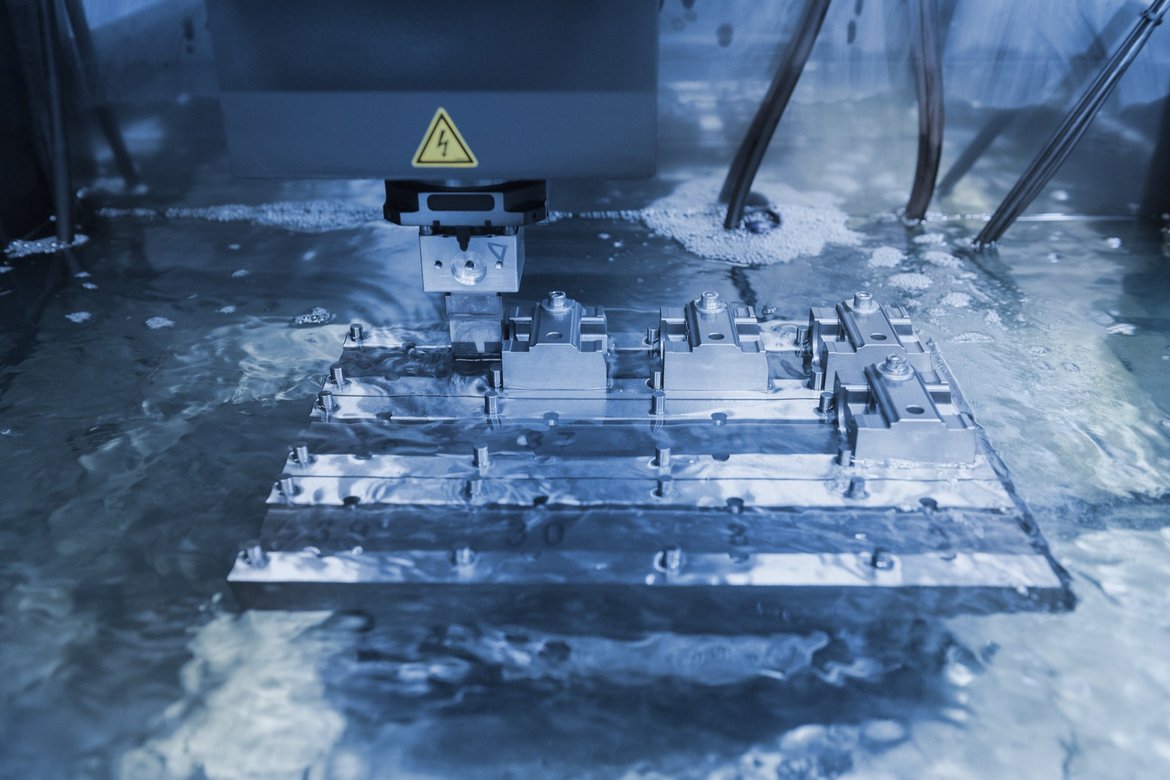

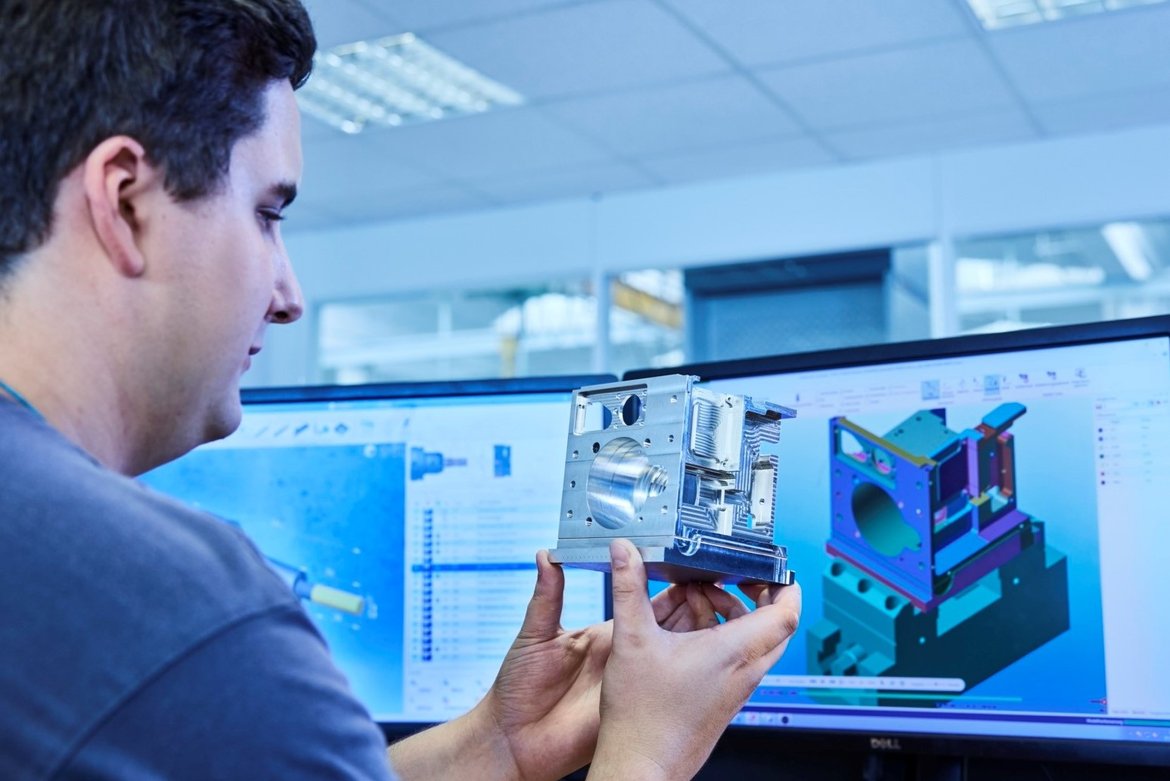

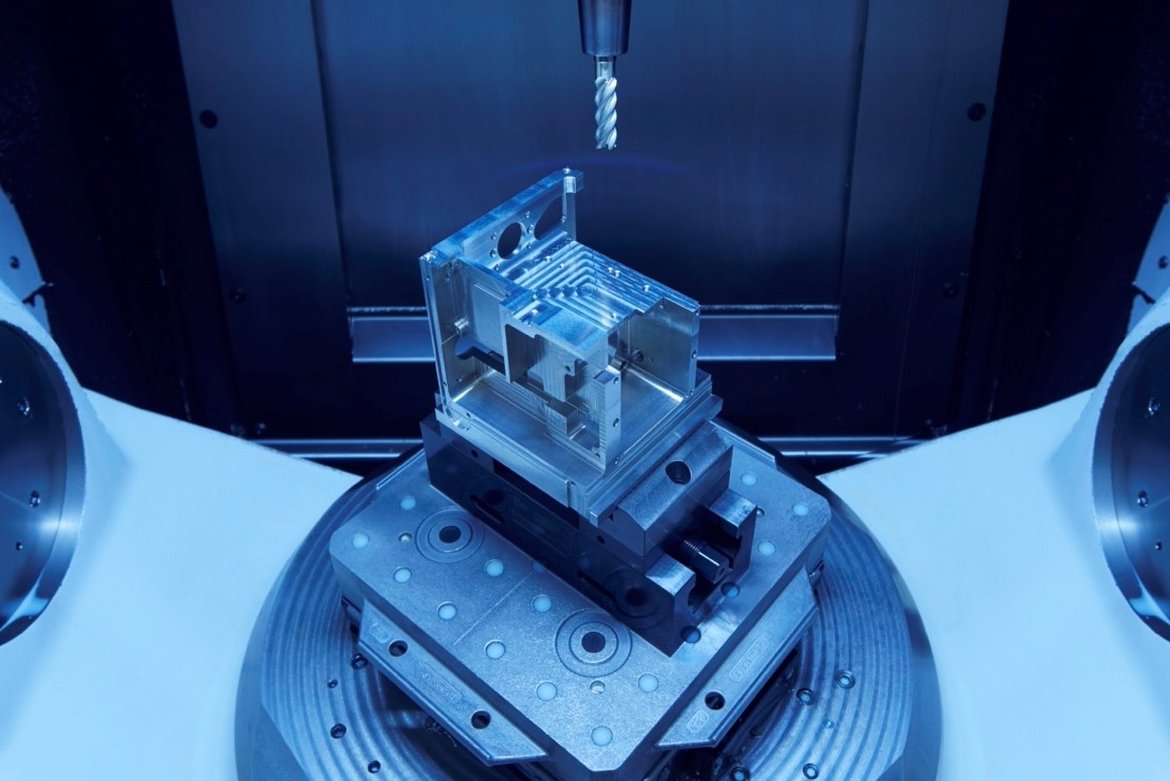

- 5-axis CNC machining of single and mass-production parts, using primarily high precision cubical and rotational machining processes in the tolerance range up to +/-3 μm. Machining of aluminium, titanium, steel and special alloys as well as cast and forged parts.

- This multiple-axis machining technology is supplemented by erosion processes, grinding technologies, laser labelling and an express workshop.

- The DIN EN 9100-2016 standard allows the company to serve the entire range of the aviation & space industry.

Contact persons