Mechanical engineering parts and components

Mechanical engineering parts and components Benefit from our broad manufacturing capabilities: from sheet metal components, mechanical engineering parts and welded constructions to sophisticated precision parts made of titanium for aerospace or components weighing up to 10 tonnes for energy technology.

Choose one of our competences and learn more:

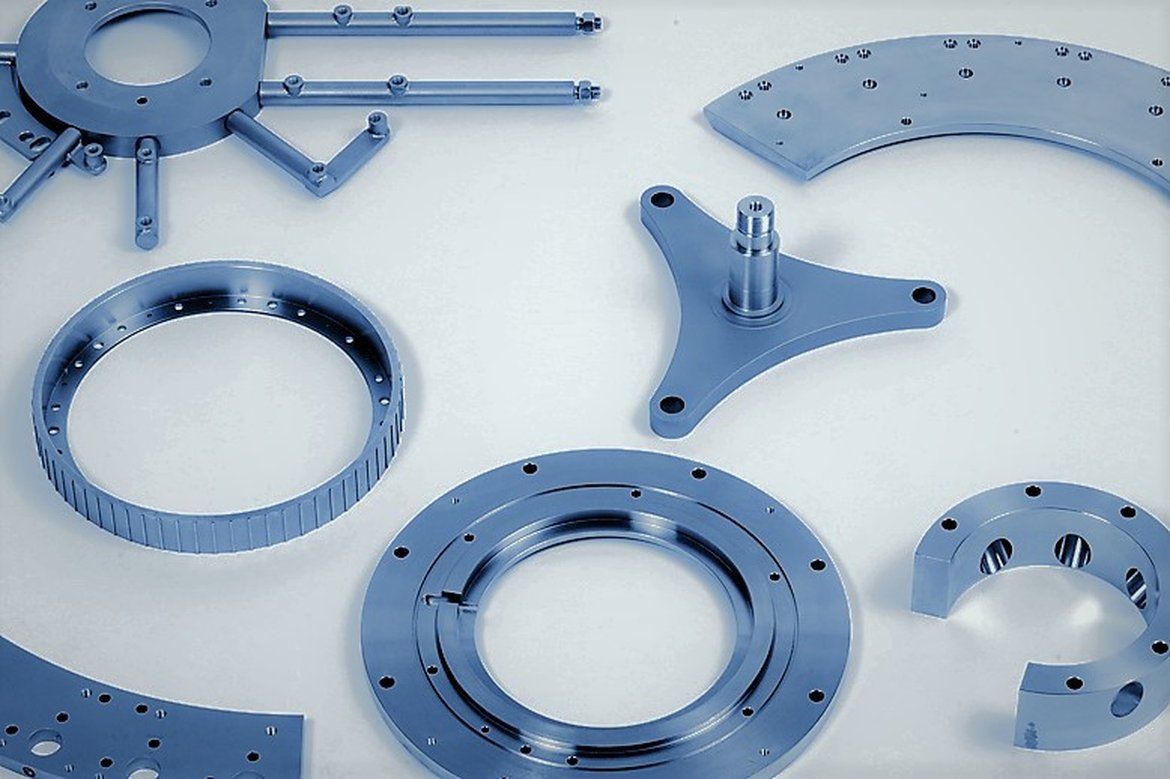

Special flanges, rings and plates

For the process industry and mechanical engineering, in rust-, acid- and heat-resistant stainless steels, structural steels, special steels or nickel-based alloys.

Know-how

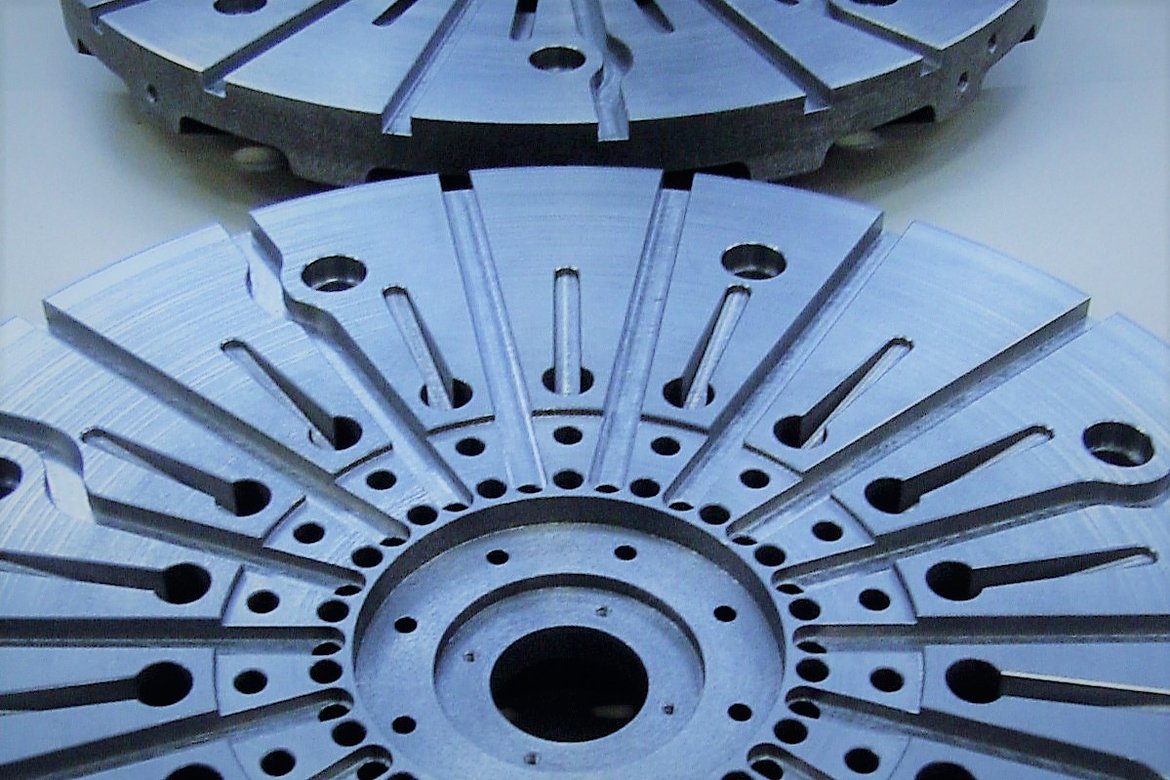

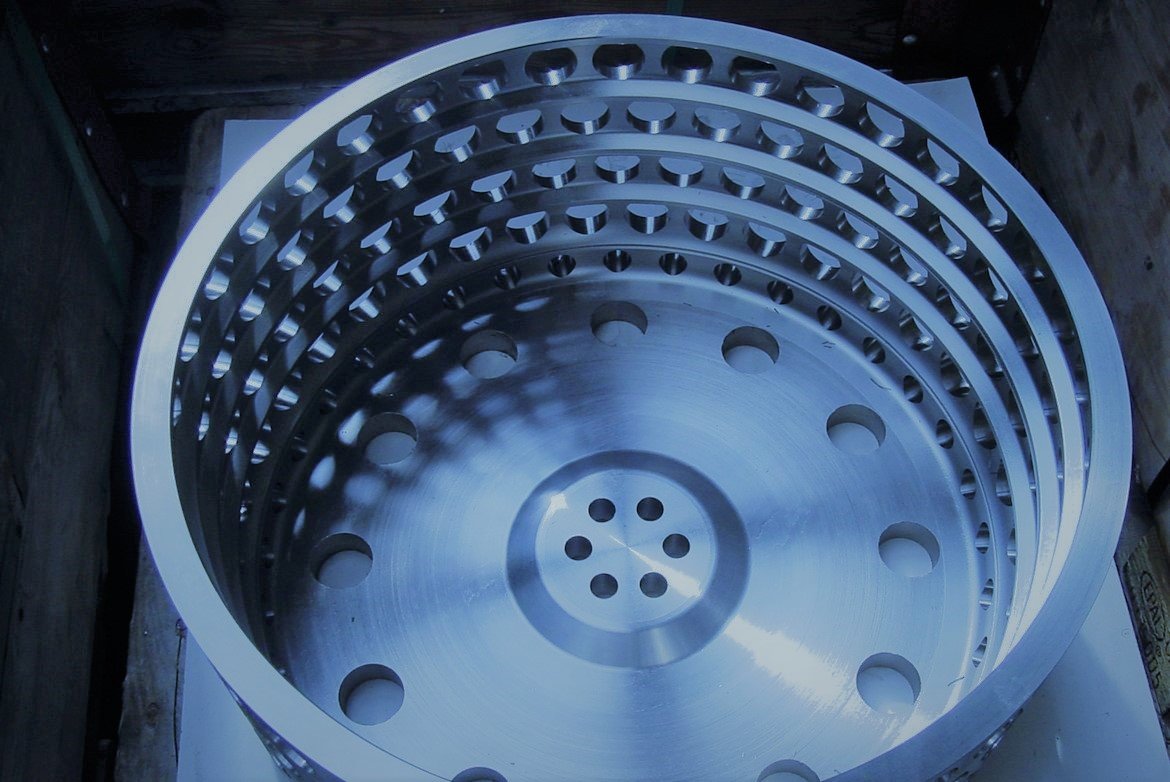

Carrier discs and plates

Production of carrier discs and plates from rust-, acid- and heat-resistant stainless steels, structural steels, special steels or nickel-based alloys.

Fulfilment of high tolerance requirements in the range of 1/100mm as well as technical and visual surface quality.

Manufacturing processes optimised by ESTECH (turning, milling, circular milling, drilling, shrink-fitting of bolts, welding, stress-relief annealing, surface treatment, CNC 3D measuring).

Diameter 500 to 3'200mm.

Special flanges and rings

Manufacture of special flanges rings and plates etc. from rust-, acid- and heat-resistant stainless steels, structural and special steels and nickel-based alloys.

Various designs, cylindrical or conical and variants such as with grooves, thin wall thicknesses, welded, etc.

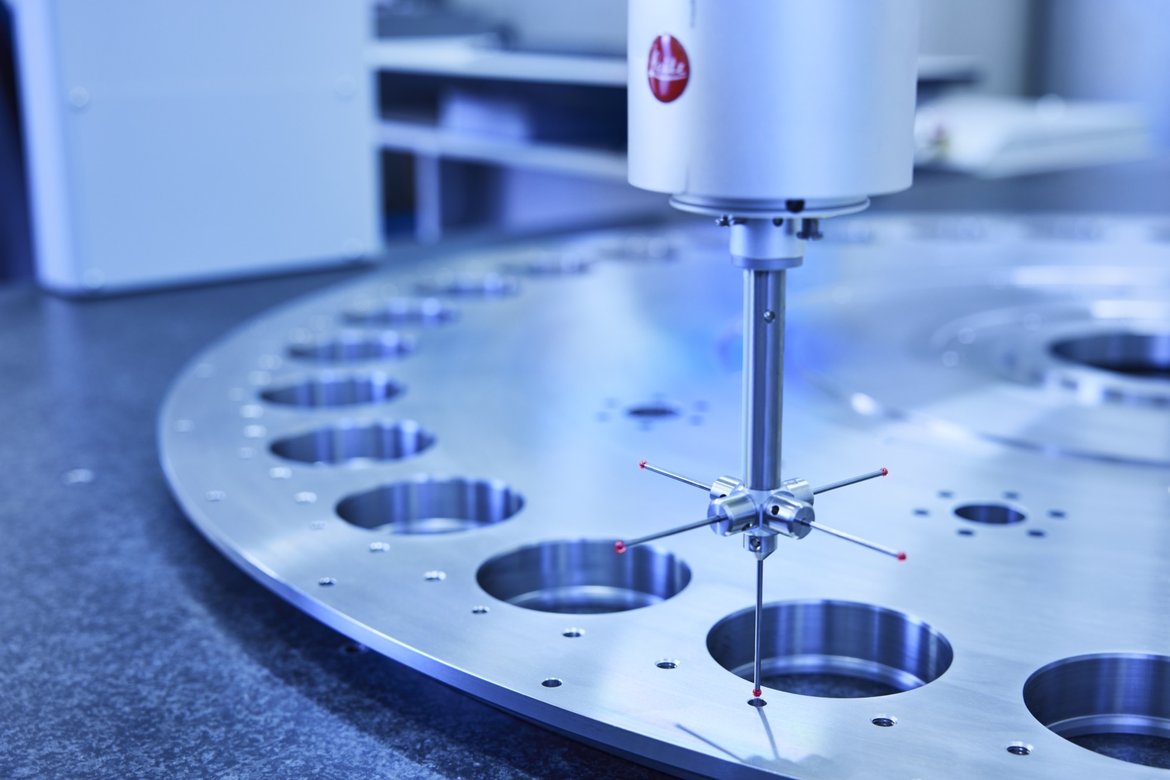

Fulfilment of high dimensional, positional and form tolerance requirements in the range of 1/100mm.

Manufacturing processes optimised by ESTECH (turning, milling, circular milling, drilling, electron beam welding, stress relieving, heat treatment, surface treatment, CNC 3D measuring).

Diameter 100 to 3'200 mm

Our large machine park includes:

- CNC horizontal and various CNC vertical lathes.

- Various CNC drilling centres and CNC milling centres as well as CNC machining centres / 5-axis machining

- Combination: Welding according to 2014/68/EU and mechanical production

- Stress relief annealing, 3D measuring machines

Working range

- CNC turning: Dmax: 3'200 Lmax: 1'500

- CNC milling: Dmax: 1'600 (5-axis machining)

- Welding technology: MIG / MAG / TIG / e-Beam / MMA

- Automation: robot welding, mechanised welding, palletising equipment for low-manpower mechanical production

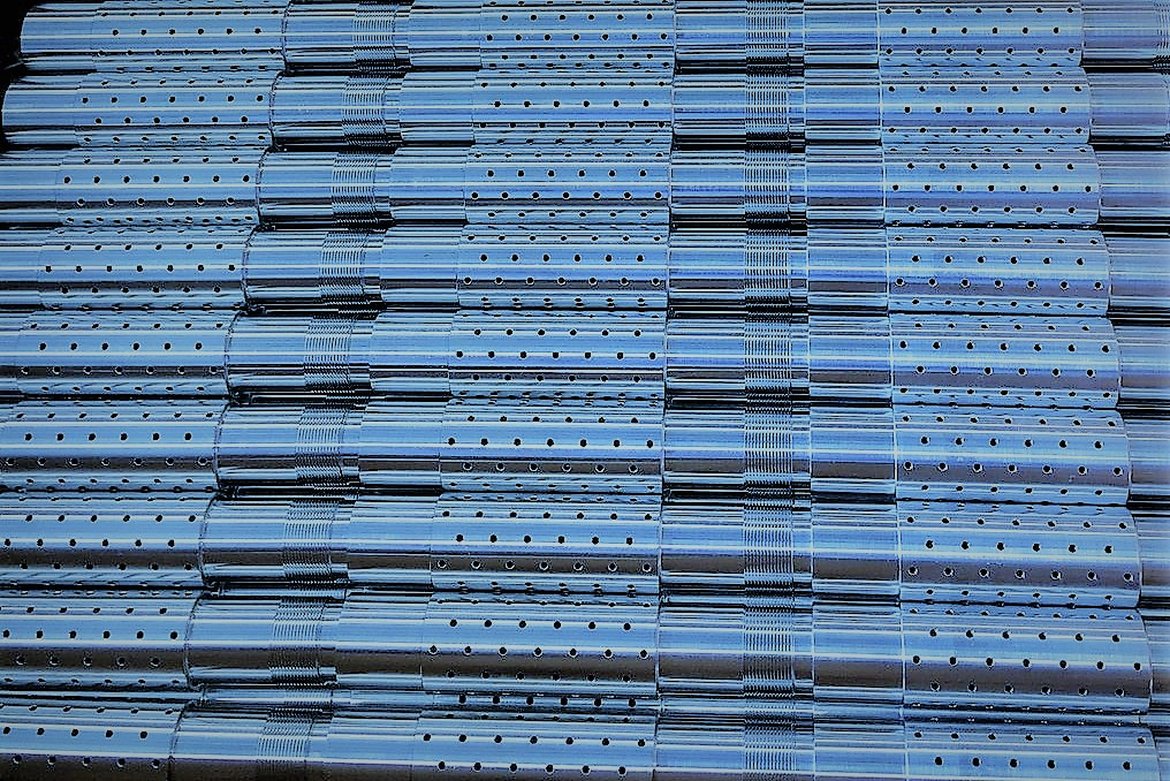

Thin-walled turned parts, sleeves, half-shells and shafts

For applications in hydraulics and pneumatics, drive systems or general mechanical engineering.

Know-how

Thin-walled sleeves

- Production of thin-walled sleeves from 0.8mm wall thickness.

- Fulfilment of extremely high dimensional tolerance requirements in the range of 1/100mm.

- Manufacturing processes developed by ESTECH (vacuum pick-up, parallel turning, stress relief method).

- Material: unalloyed and alloyed steels, aluminium; manufactured from solid or moulded material. Diameter up to 300mm, length up to 300mm

Half shells

- Manufacture of dimensionally accurate pairs of shells.

- Manufacturing processes developed by ESTECH (turning, drilling, electro-erosion, grinding, laser marking with graphics capability).

- Material: alloyed, wear-resistant steels.

- Diameter up to 300mm, length up to 300mm

Cylinders

- Production of cylinders in alloyed and unalloyed steels, with diameters up to 300mm and lengths up to 300mm.

- Fulfilment of high dimensional tolerance requirements in the range of 1/100mm.

- Manufacturing processes optimised by ESTECH (turning, drilling, grinding, heat treatment, surface treatment, CNC 3D measuring).

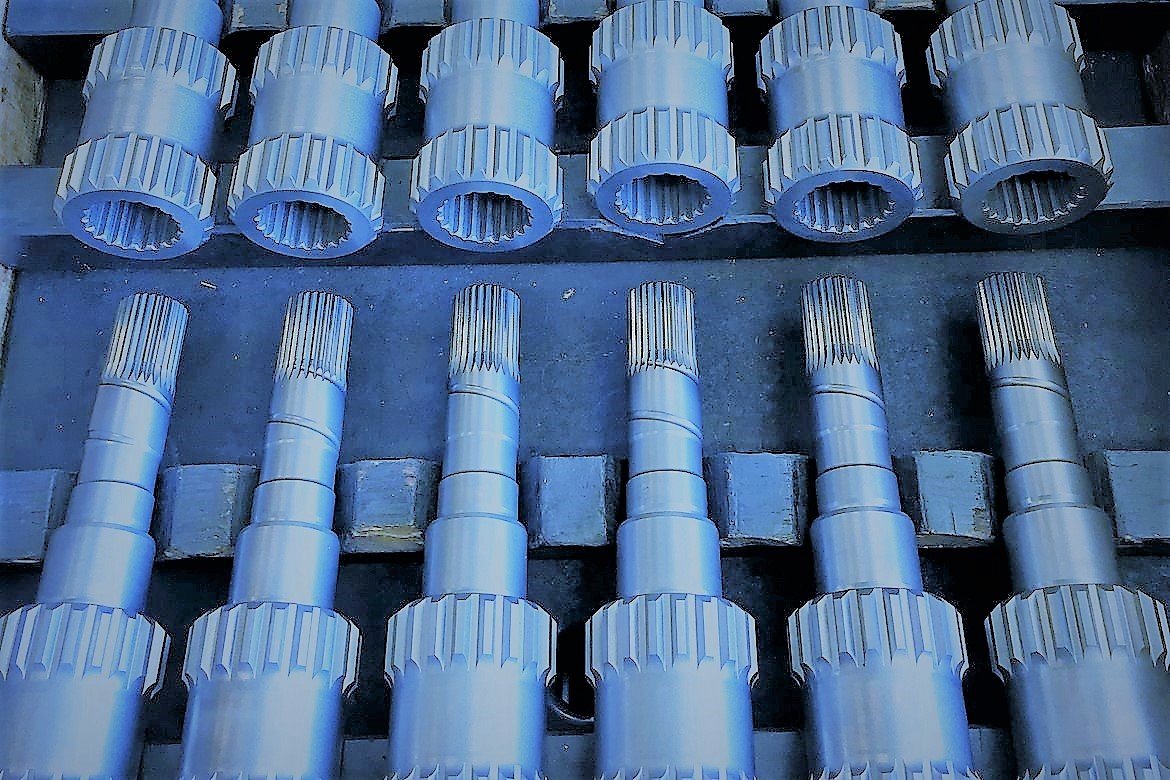

Drive shafts

- Manufacture of drive shafts in a wide variety of designs in alloyed and unalloyed steels, with diameters up to 300mm and lengths up to 1,500mm.

- Manufacturing processes: Turning, drilling, grinding, spline shaping / broaching, welding, balancing.

Extrusion screws - elements

- Production of extrusion screws and elements in various designs in alloyed and unalloyed steels, with diameters up to 250mm and lengths up to 1'500mm, resp. 300mm (elements).

- Erfüllung hoher Mass - Toleranzanforderungen im Bereich 1/100mm.

- Manufacturing processes: 5-axis milling, drilling, heat treatment, trovalising, wedge path piercing / broaching, welding, CNC 3D measuring.

Rotors and stators for electric motors

- Manufacture of rotors and stators in a wide range of designs and variants in alloyed and unalloyed steels, forgings or castings.

- Fulfilment of high dimensional - tolerance requirements in the range of 1/100mm.

- Manufacturing processes: Turning, milling, drilling, grinding, surface treatment, welding, trovalising, laser marking with graphics capability, CNC 3D measuring.

- Material: unalloyed and alloyed steels, forgings, castings.

- Diameter up to 1'200mm, length up to 400mm.

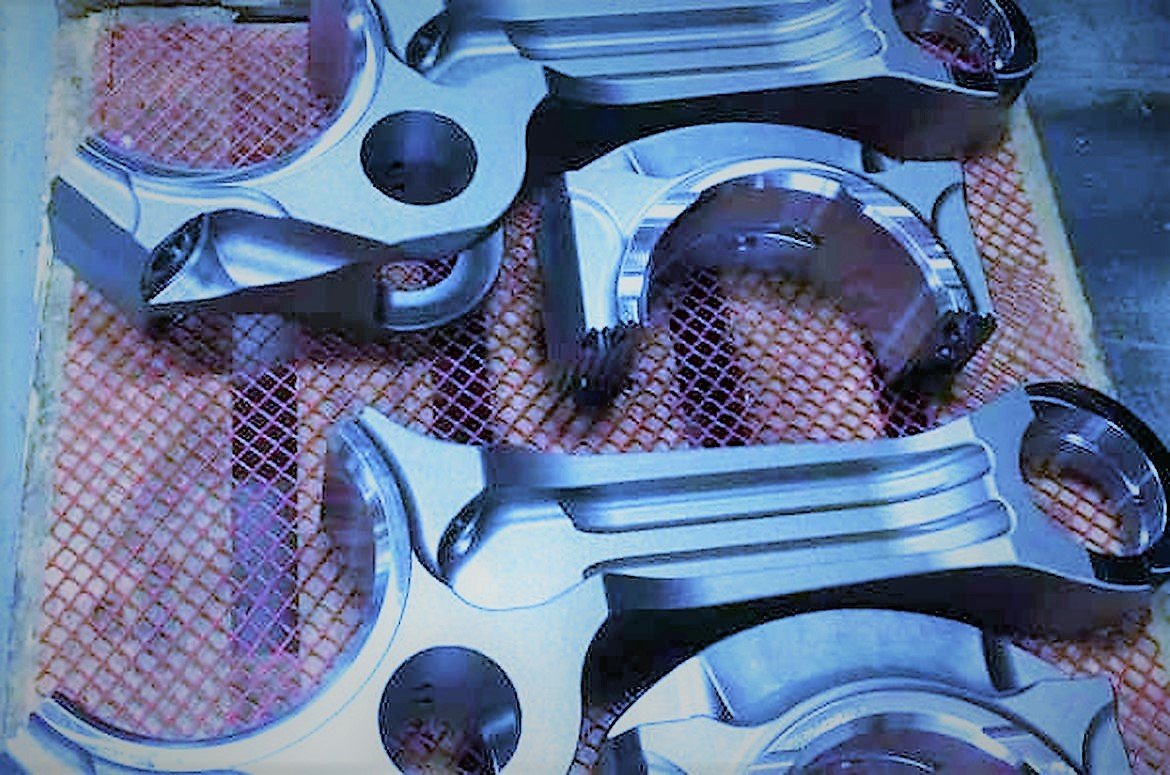

Connecting rods, cylinder heads and cylinder blocks

Parts and components for large diesel engines and drive systems

Know-how

Connecting rods

- Production of main and auxiliary connecting rods for large diesel engines and power units.

- Fulfilment of high strength requirements as well as high dimensional tolerance requirements in the range of 1/100mm.

- Manufacturing processes developed by ESTECH (milling, drilling, grinding, gear cutting, surface treatment, finishing).

- Material: alloy steels, forgings. Length up to 1'200mm

Cylinder heads

- Production of cylinder heads / cylinder covers for larger diesel engines.

- Fulfilment of high dimensional tolerance requirements in the range of 1/100mm.

- Manufacturing processes developed by ESTECH (milling, drilling, grinding, finishing).

- Material: nodular cast iron. Length up to 400mm, width up to 400mm, height up to 400mm.

Cylinder blocks

- Production of cylinder blocks for larger diesel engines.

- Fulfilment of high dimensional tolerance requirements in the range of 1/100mm.

- Manufacturing processes developed by ESTECH (milling, drilling, grinding, finishing).

- Material: lamellar cast iron, nodular cast iron. Length up to 1'200mm, width up to 400mm, height up to 1'000mm.

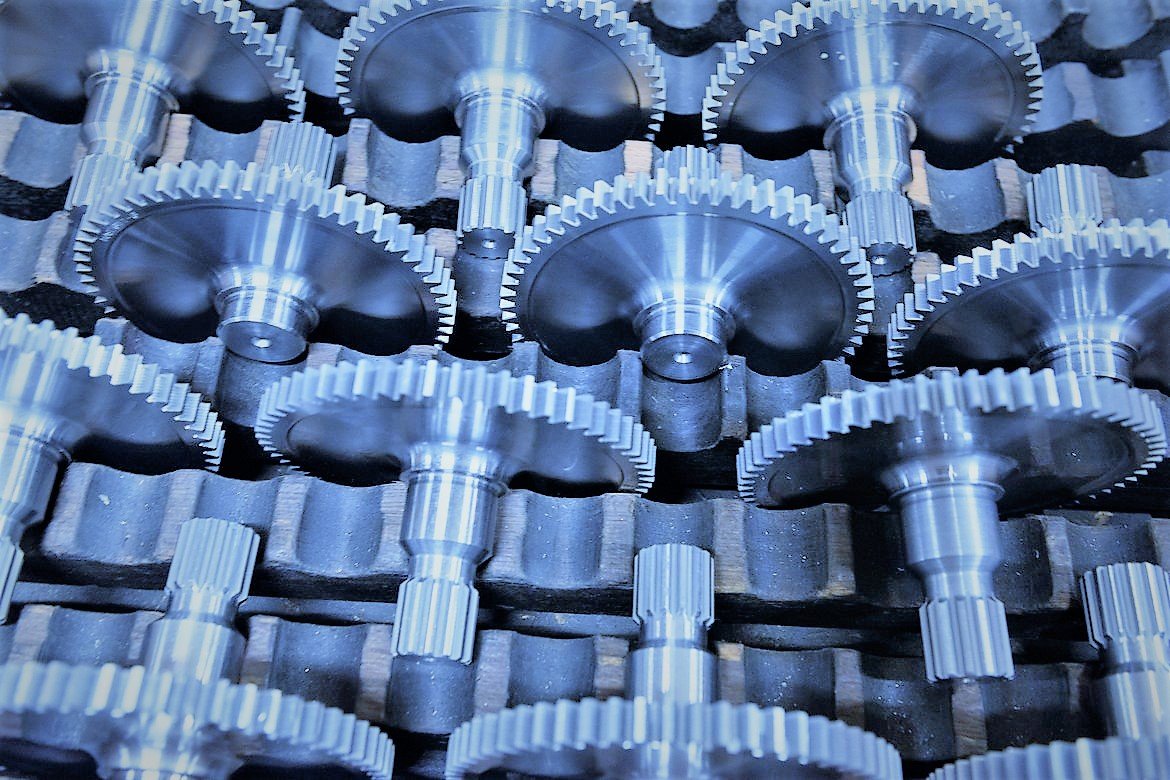

Precision parts and gear components

The production of sophisticated high-precision mechanical components, gear parts and high-quality gears, internal gearing or splines is one of our core competences. To keep the gears turning.

Know-how

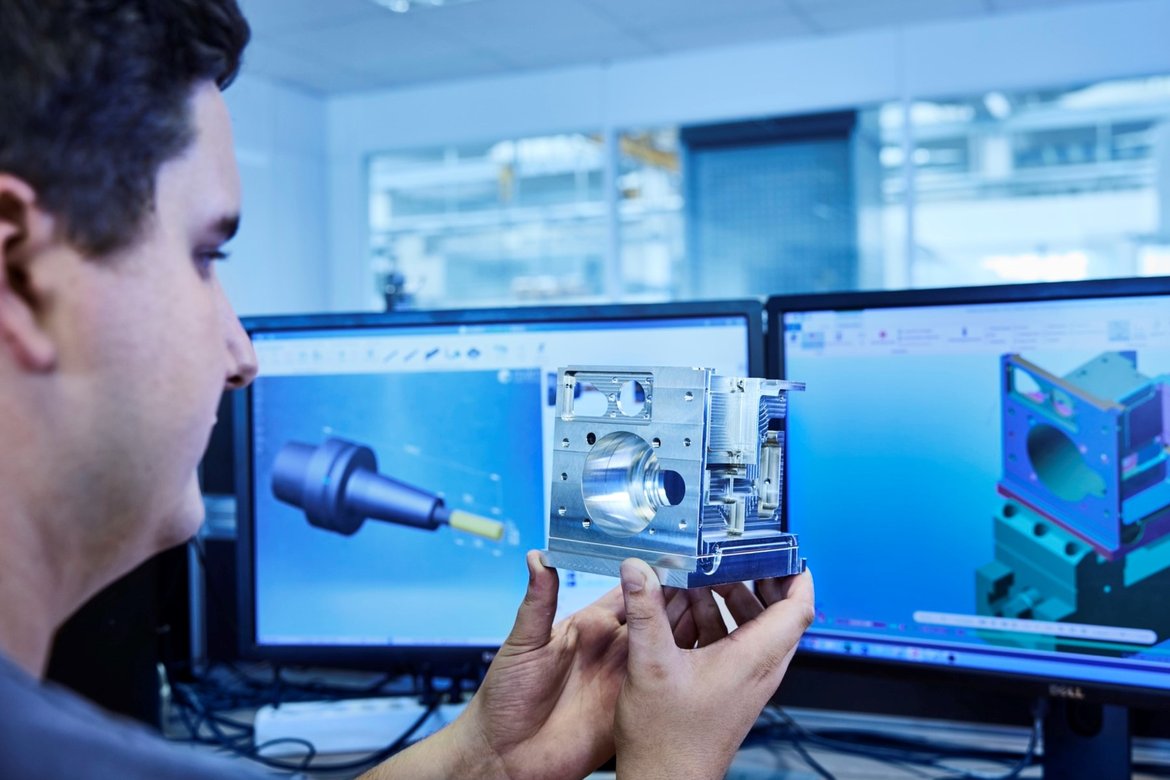

Precision parts

Manufacture of precision housings, rings, instrument carriers, sensor housings, hydraulic blocks, cylinders, sleeves, thin-walled parts, camera housings, bearing housings, covers, azimuth housings, holders, cross pieces, flow regulators, etc..

Fulfilment of high form and dimensional tolerance requirements in the range from 3 micrometres.

Manufacturing processes optimised by ESTECH (3 to 5-axis milling, profile milling, free-form milling, drilling, thread cutting, turning, grinding, stress-relief annealing, broaching, shaping, 2D/3D wire-cut EDM, die-sinking EDM, heat treatment, surface treatment, hollowing, lapping, laser marking with graphics capability, CNC 3D measurement).

Low to high alloy steels, aluminium, titanium, stainless steel

Lengths up to 400mm, width up to 250mm, height up to 250mm

Our large machine park includes various programmable CNC laser engraving machines.

Input: Customer-specific specifications in STEP or DXF formats

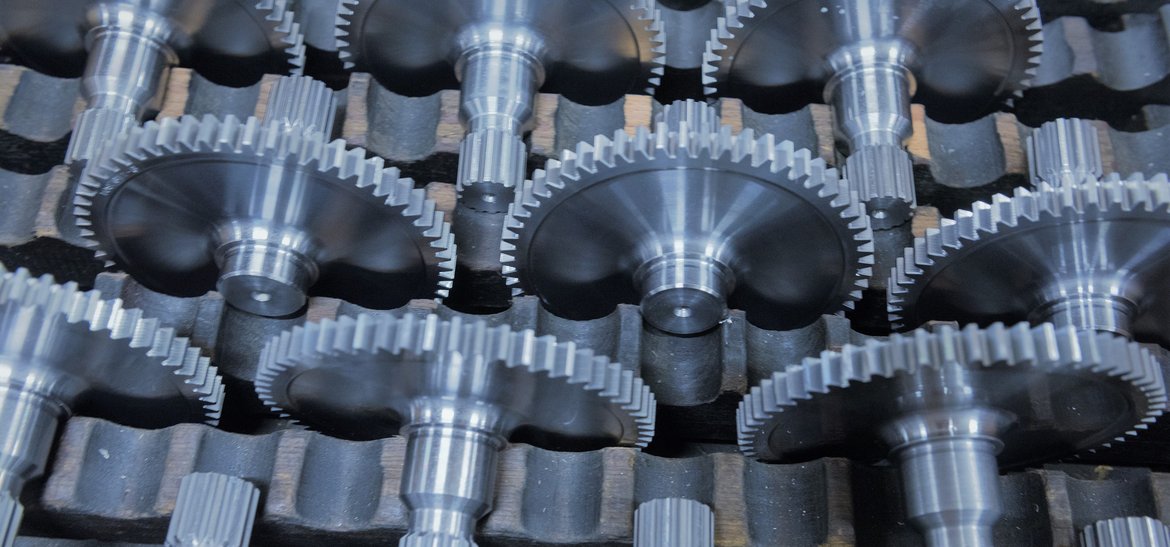

Gear wheels and gear parts

Production of pinions, gears, spur gears, elliptical gears, bevel gears, pignons, crown gears, worm gears. With helical, straight or involute toothing.

Fulfilment of high strength requirements and high dimensional tolerance requirements.

Manufacturing processes developed by ESTECH (turning, drilling, gear cutting, profile milling, free-form milling, broaching, shaping, gear grinding, profile grinding, spline profile grinding, hollowing, lapping, heat treatment, surface treatment, laser marking with graphics capability, CNC 3D measurement).

Alloy steels. Module 1 to 6.

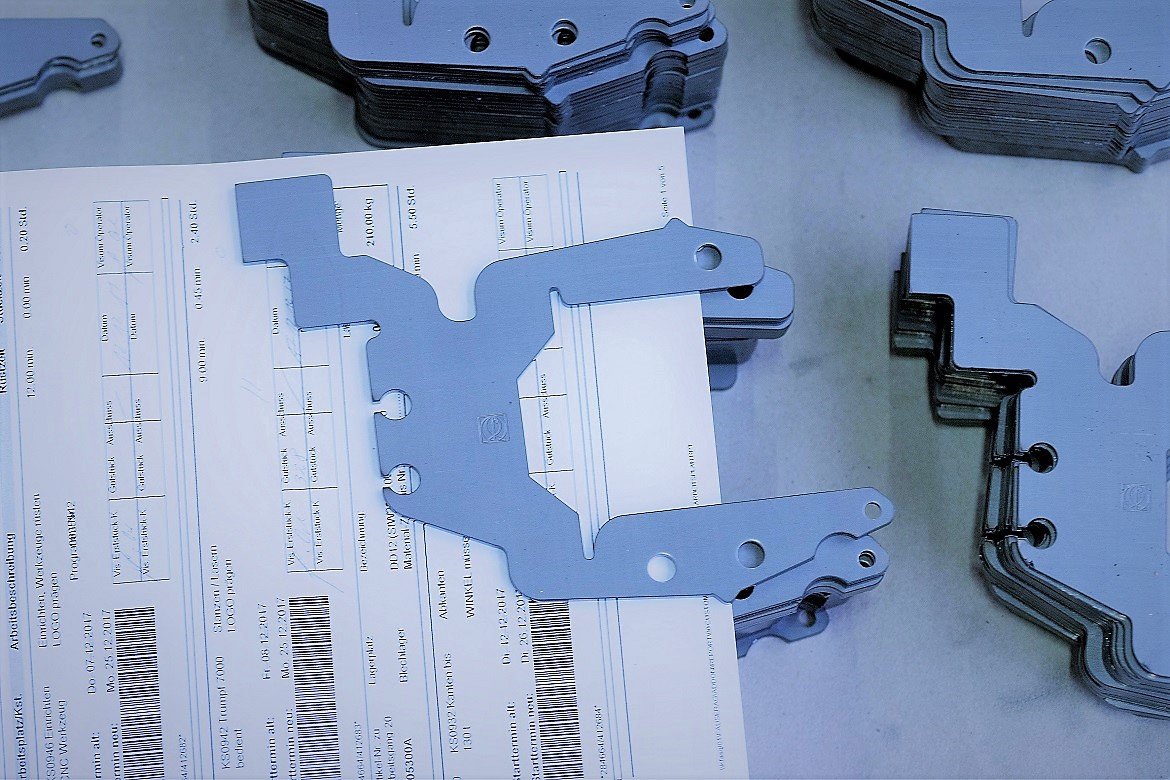

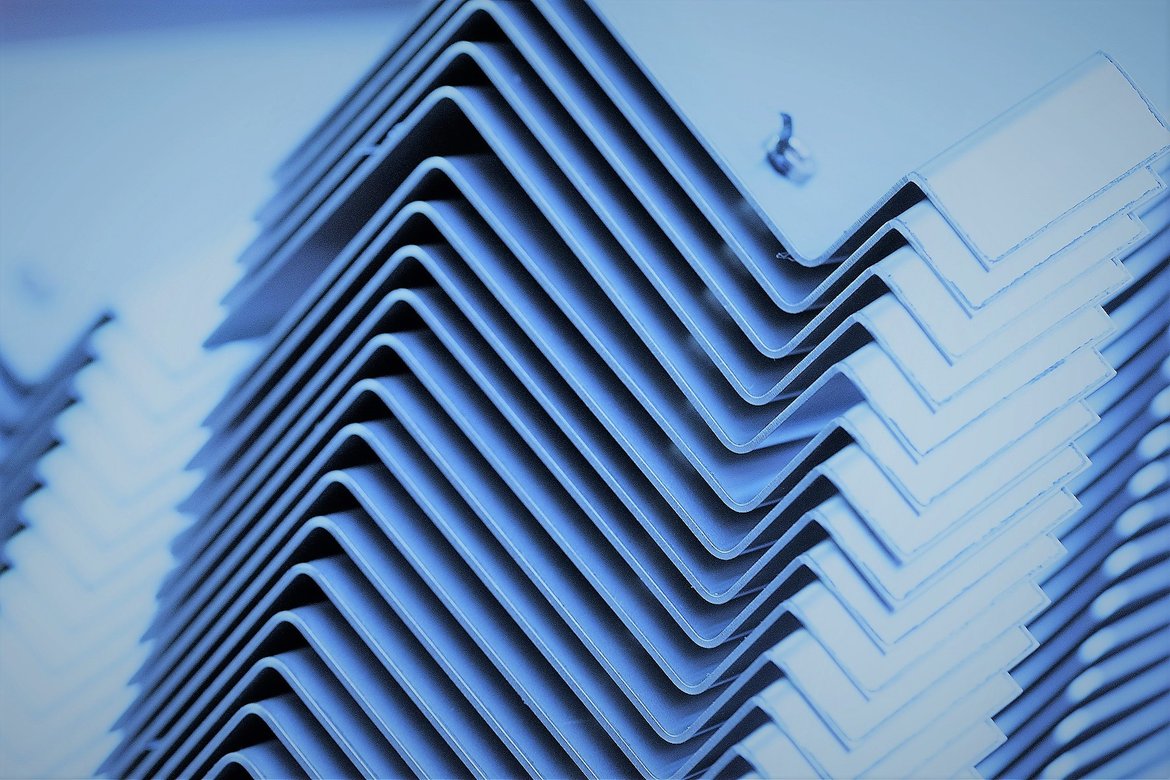

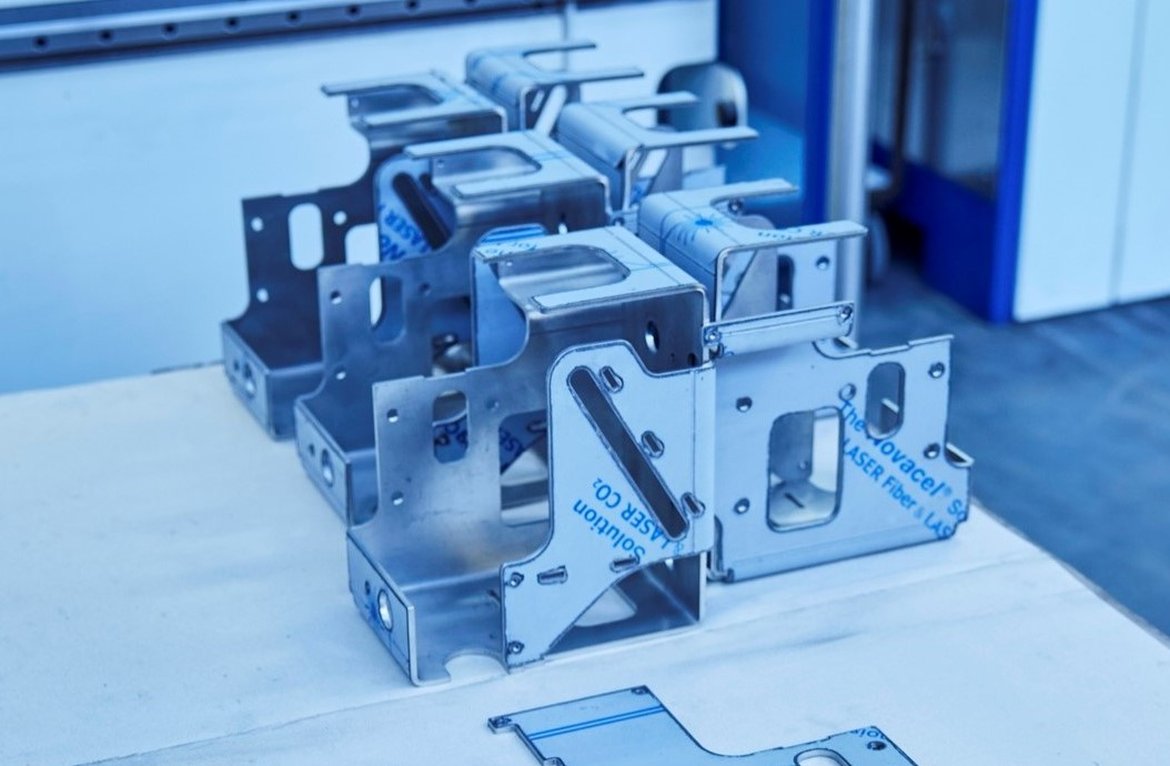

Sheet metal parts

On our modern sheet metal processing machines, we manufacture a wide range of components and assemblies according to drawings (pdf., STEP. or dxf. format). We offer design, production (laser cutting - punching - bending - welding) and assembly from a single source.

Know-how

CNC complete processing Trumpf Trumatic 7000: laser cutting and punching on one system

Automated sheet metal infeed and outfeed, including automatic sheet metal storage, enables virtually unmanned production. The complete processing often makes downstream work steps, e.g. deburring or thread cutting, superfluous.

Bending / deburring

Production of housings, profiles, casings, etc. using Trumpf press brakes. Deburring for the perfect finish with complex geometries and maximum surface requirements.

Welding / Assembly

From sheet metal welding assemblies to ready-to-install systems - We take on every challenge - Test us!

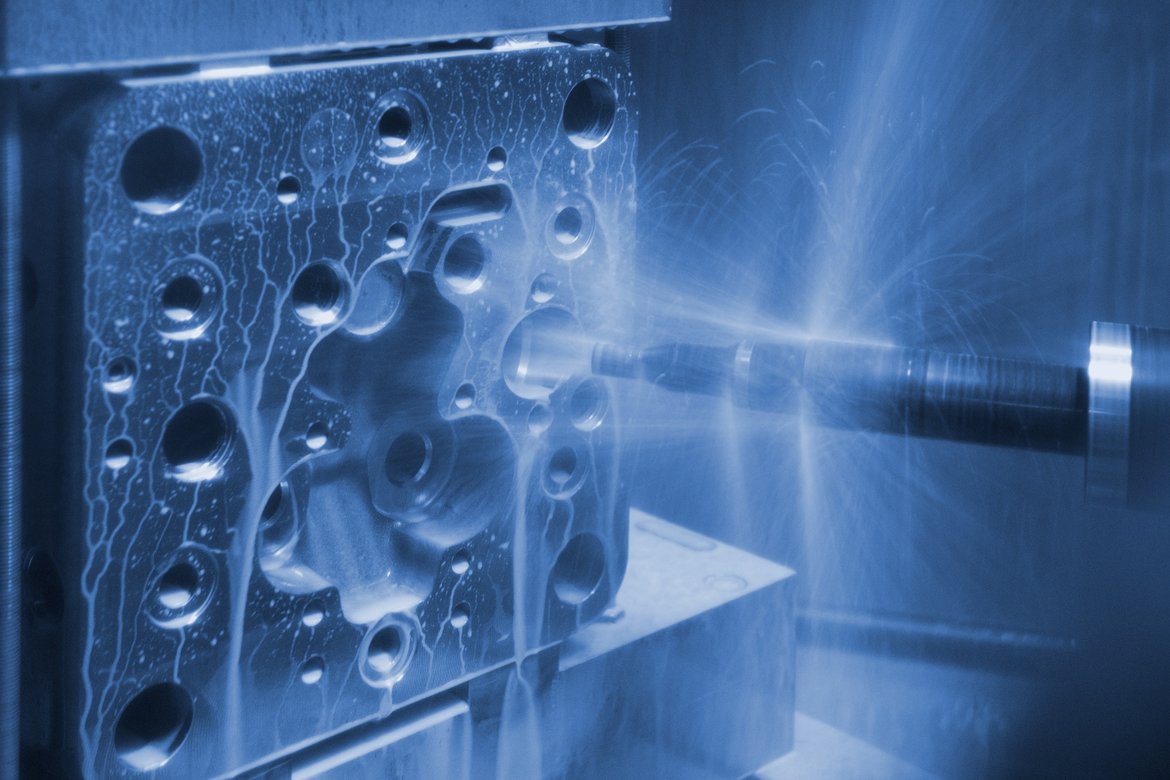

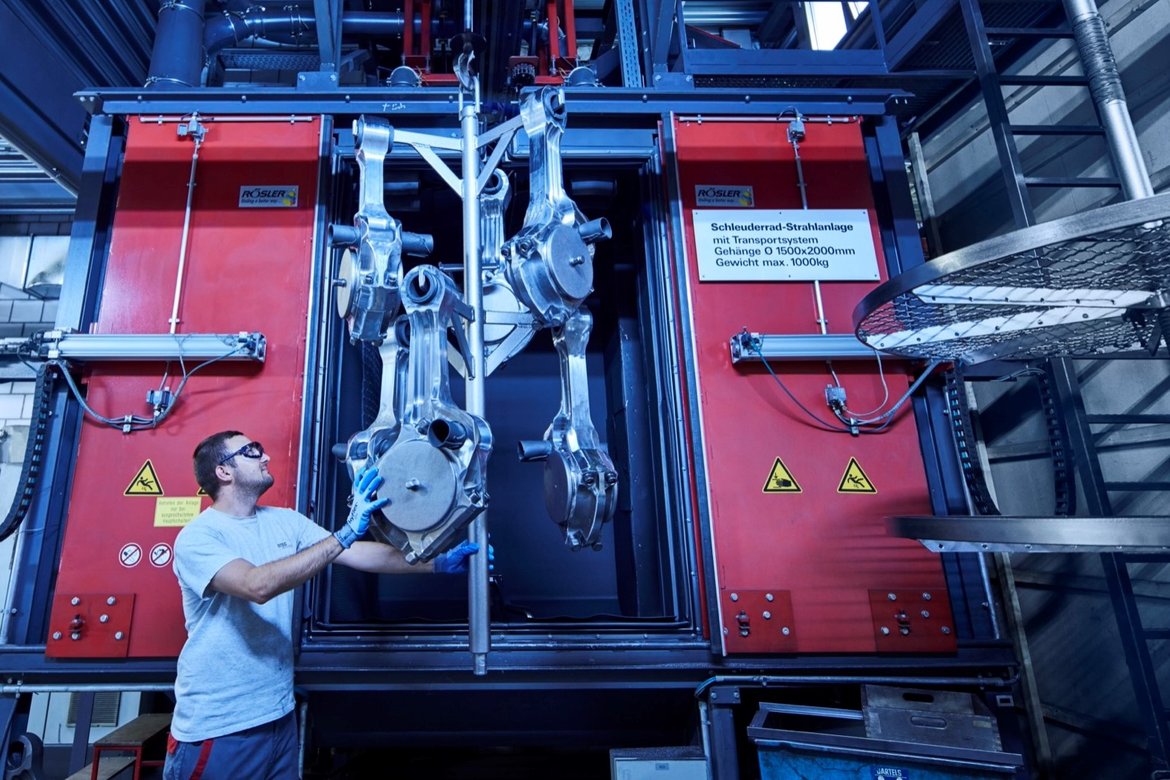

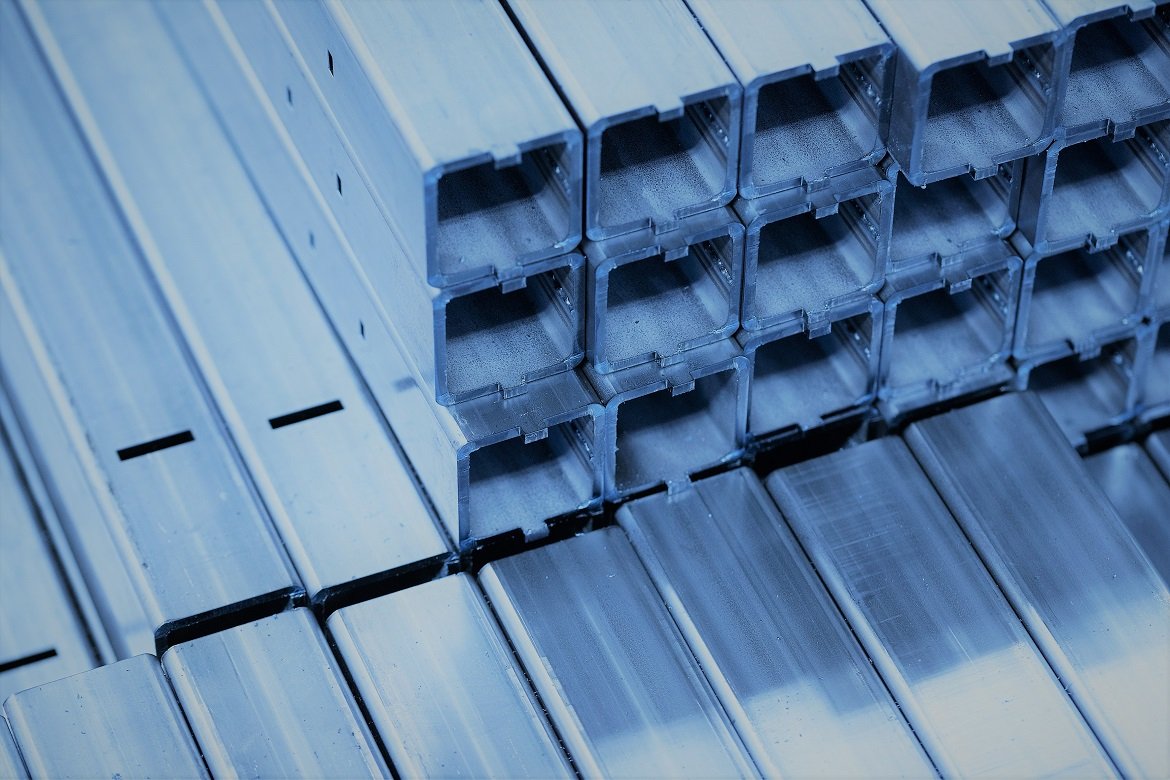

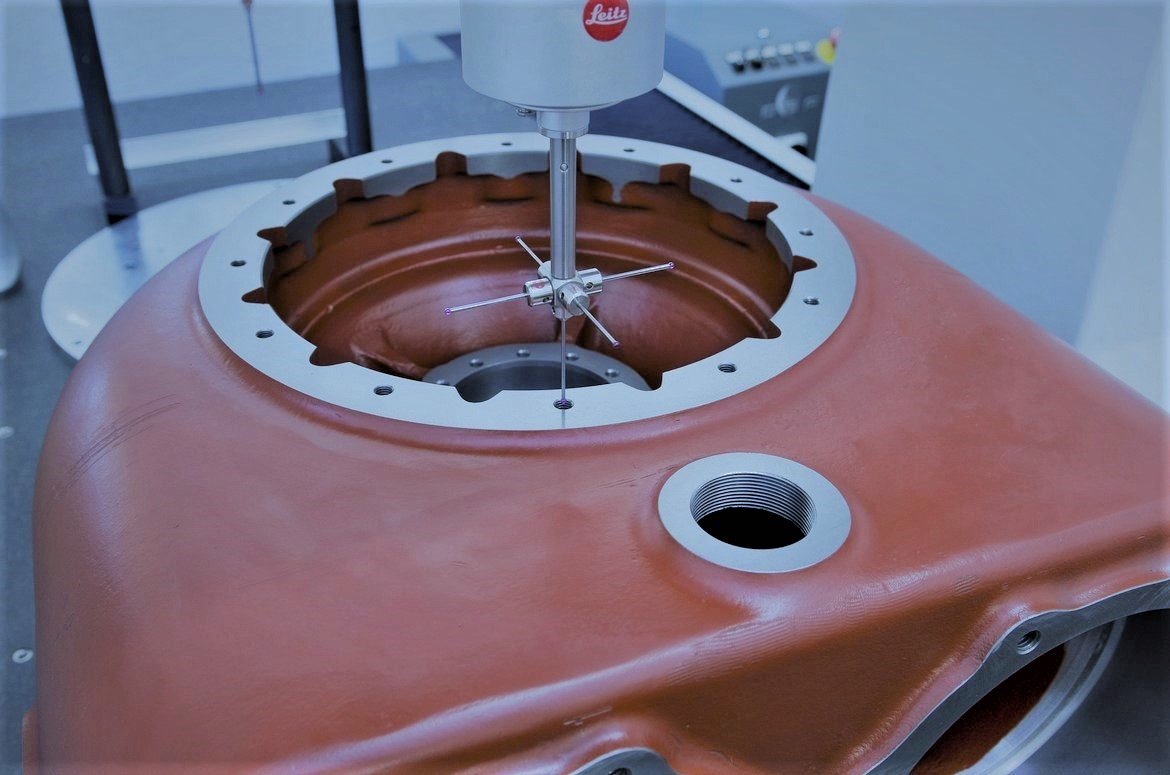

Contract manufacturing: Iron or steel casting, forged parts

We are your partner for contract work! We advise you competently from the idea to the execution.

Know-how

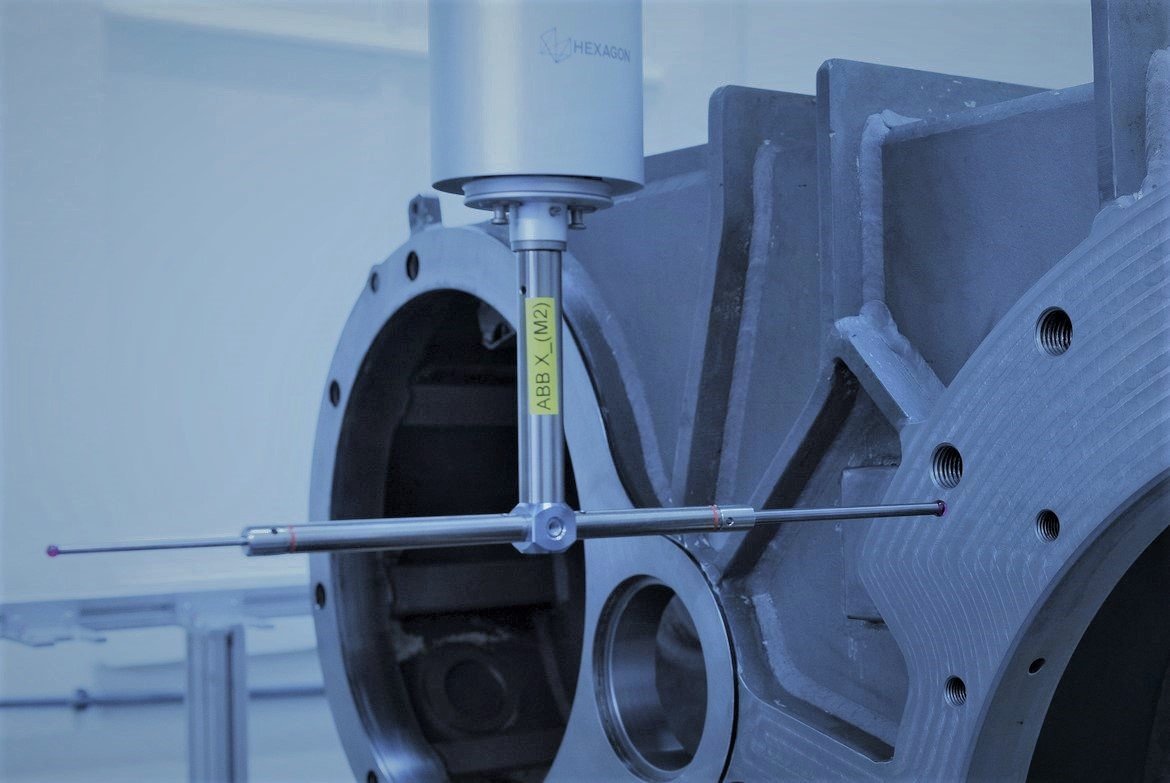

Machining of iron castings, steel castings, investment castings stainless steel

Manufacture of compressor housings, pump housings, gearbox housings, planetary carriers, sleeve housings, filter frames, precision housings, bearing housings, spiral housings, shaft protection sleeves, box elements, construction parts, rubber cylinders, trailing arms, swing arms, yoke tubes, steering knuckle carriers, vehicle parts.

Fulfilment of high form and dimensional tolerance requirements in the range of 1/100mm.

Manufacturing processes optimised by ESTECH (milling 3- to 5-axis, carousel turning, drilling, deep-hole drilling, thread cutting, welding, stress-relieving annealing, surface treatment, industrial high-pressure washing to remove chips, CNC 3D measurement).

Material: Lamellar cast iron, nodular cast iron, cast steel, forgings, solid material.

Length up to 1'600mm, width up to 1'500mm, height up to 1'200mm.

Forged parts or welded constructions

Manufacture and machining of parts and components for energy technology, the process industry or mechanical engineering, e.g. centrifuge drums, high-pressure components, special bottles, etc..

Fulfilment of high form and dimensional tolerance requirements in the range of 1/100mm.

Manufacturing processes optimised by ESTECH (carousel turning, drilling, milling, thread cutting, stress relieving, surface treatment, laser marking with graphics capability, CNC 3D measurement, certified welding.

Material: Alloy steels, stainless steels, cast steels, forgings, solid or shaped material.

Diameter up to 2'000mm, height up to 1'500mm.

DO YOU HAVE ANY QUESTIONS ABOUT OUR OFFER? WE WILL BE HAPPY TO ANSWER.

Contact persons

Sales

SALES- FRENCH, ITALIAN AND SPANISH SPEAKING REGIONS & COUNTRIES

Management