Measuring - Testing - Cleaning

In order to guarantee the permanently high quality standard of our production, we use specific measuring and testing techniques.

In-process inspections, final inspections on our 3D coordinate measuring machines as well as specific tests in the areas of welding technology, materials and surfaces are the basis for the highest repeatability and precision.

Choose one of our competences and learn more:

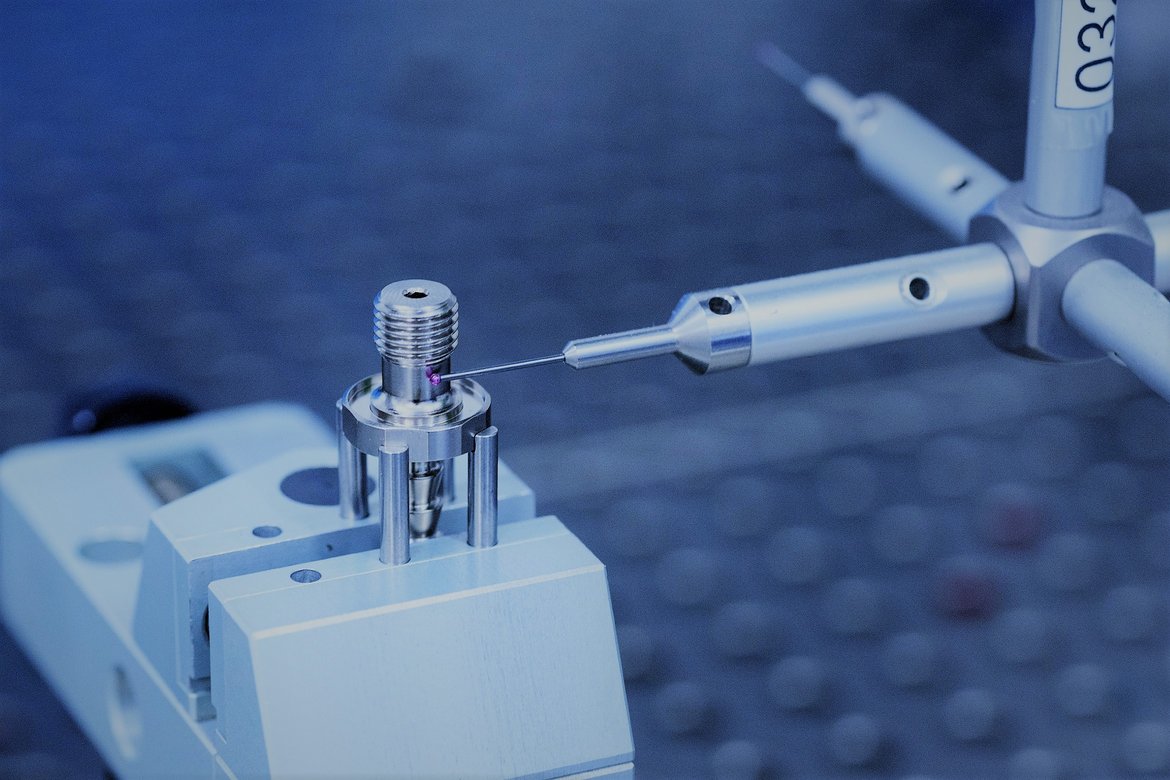

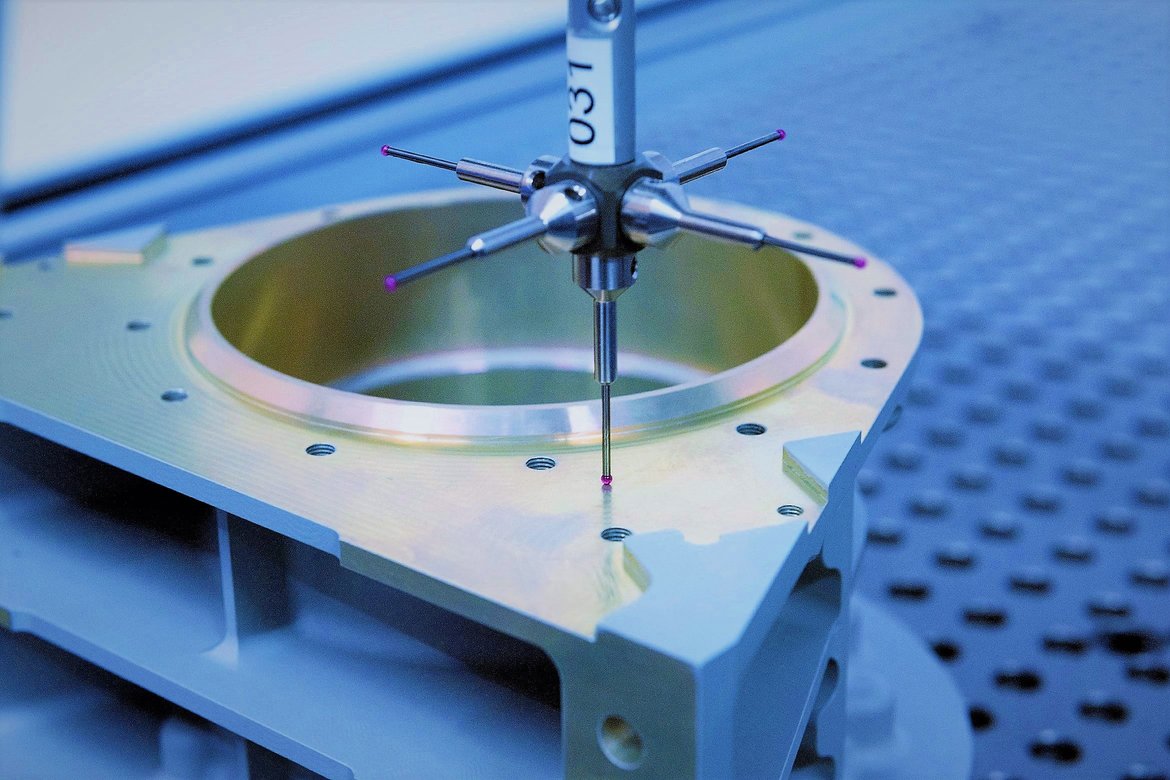

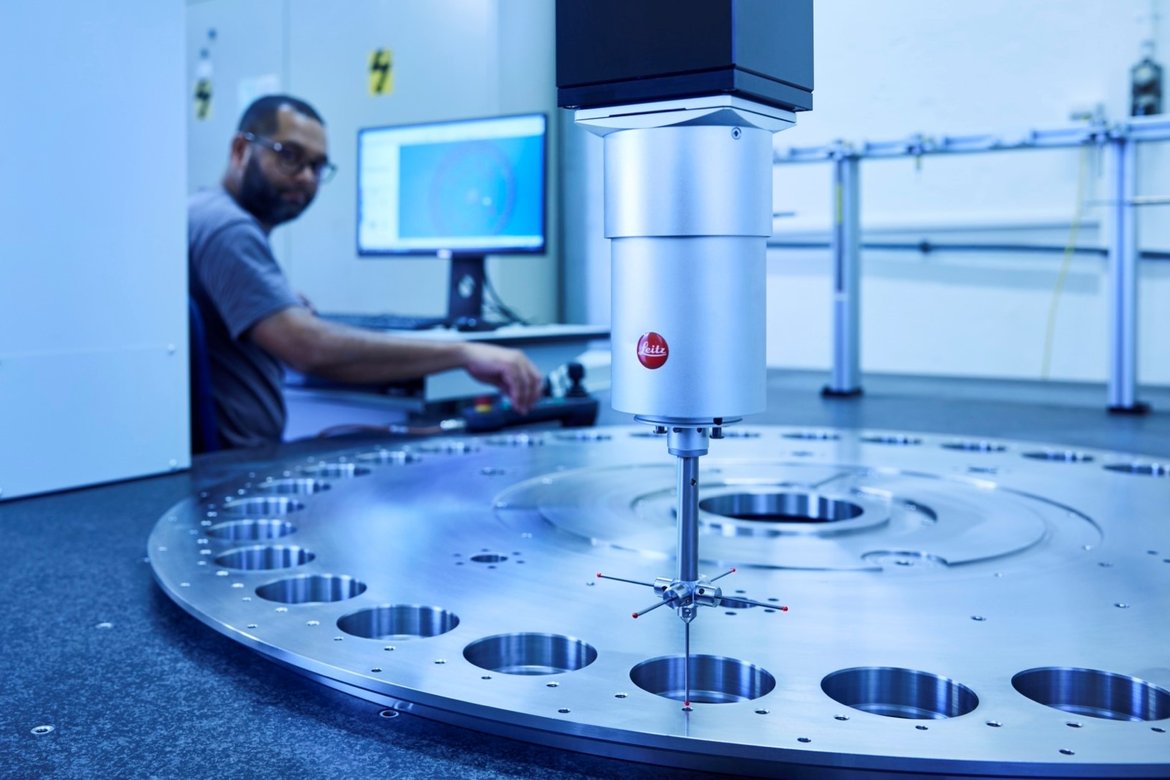

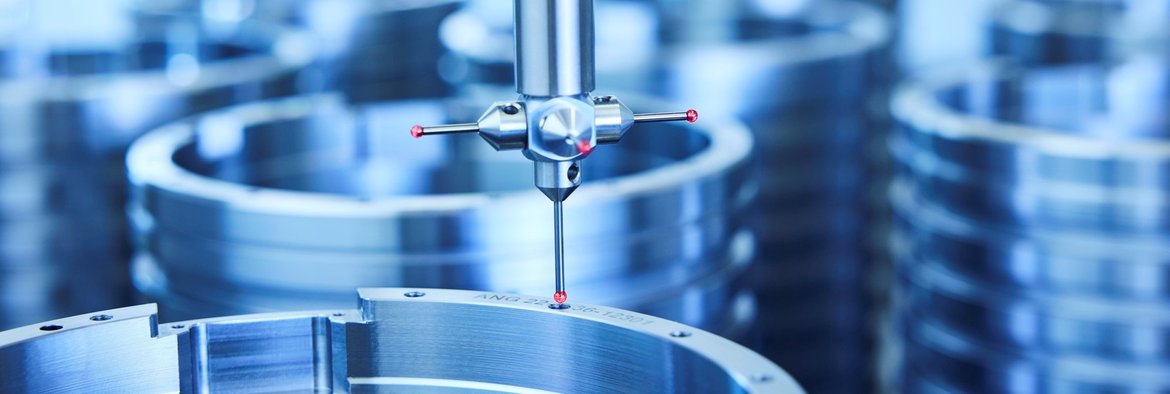

3D coordinate measuring

Trust is good, control is better. A machine CNC measurement allows 100% quality and full traceability. So that your parts reach the final assembly without errors and quickly.

Know-how

Each of our production sites has several modern and high-precision 3-D measuring machines, some of which have large traverse paths. They are housed in temperature-controlled, air-conditioned measuring rooms for constant measuring conditions.

The measuring process is defined and carried out in close coordination with the quality requirements and the needs of our customers. The measurement protocols form the basis for achieving consistently high quality.

Our large machine park includes:

- Modern 3-D CNC measuring machines from renowned manufacturers. Measurement scanning tactile or by scanning

- Extensive accessories: Large selection of measuring probes and clamping devices

WORKING RANGE

- Various 3-D CNC measuring machines: Xmax: 1'500 Ymax: 2'000 Zmax: 1'400

- Precision: E0 MPE = 3.0μm L/333

- Table load: 2'000 kg max.

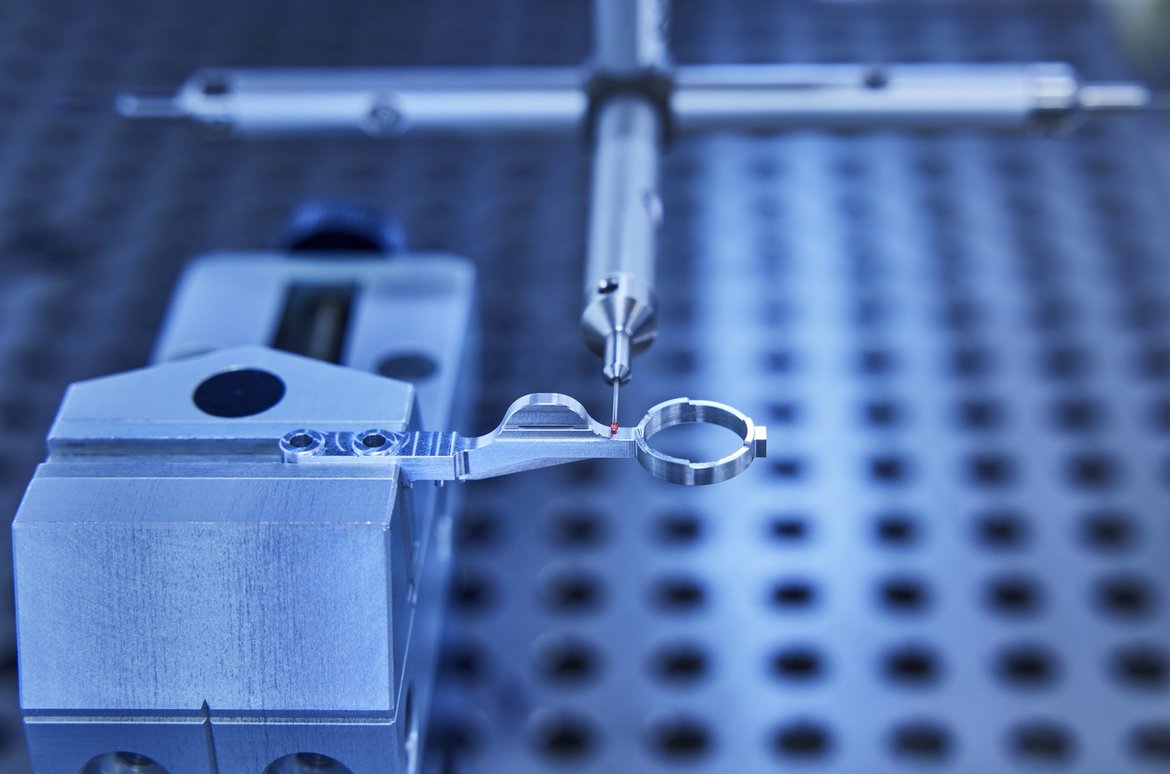

In-process control

Ensuring the correct product quality and conformity through defined in-process and spot checks during the production process along all stages of the value chain.

Know-how

Quality inspections integrated into the production process and a high level of process reliability for rework-free production.

The measurement results of the in-process control are evaluated within the framework of continuous improvement according to ISO 9001.

Measuring equipment

All the necessary measuring and testing equipment, which is monitored and regularly calibrated as part of our management system, is used for the in-process controls. The extensive range includes:

- Manual measuring equipment: digital calipers, external and internal micrometers, limit plug gauges, thread plug gauges and many more.

- In-process measuring stations: Measuring plates with measuring and articulated stands with digital dial gauges.

- Faro measuring arm

Surface testing / material identification

The verification of surface and material requirements is of great importance, especially for functional and safety-relevant components.

Know-how

Within the scope of surface testing, we provide proof that the properties of the surface of the finished workpiece correspond to the defined requirements and that the tolerances are adhered to.

For this purpose, modern and calibrated roughness measuring devices and coating thickness measuring devices are available at all our locations. In addition, we also work closely with long-standing partner companies.

As a matter of principle, we only purchase our raw materials and semi-finished products from certified manufacturers that are monitored by accredited institutes (usually TUeV) and have the corresponding verification documents in accordance with EN 10204/3.1.

In addition, we monitor material conformity by accredited testing institutes by means of material analyses.

The identification of components is carried out by means of various marking options (including laser engraving) and allows article identification with details such as article number, serial number, melt, manufacturer, manufacturing date, etc.

X-ray, dye penetration tests, pressure tests

The verification of intact surface and material properties of welded parts is becoming more and more important.

Know-how

The execution of the prescribed test procedures such as X-ray, dye penetration tests or pressure tests as well as the preparation of the verification documents are part of our standard.

Our production sites for welded parts and components have the necessary and suitable testing equipment.

For the detection of cracks, we use dye penetration tests, while in the area of material and weld seam testing, we carry out X-ray tests as well as pressure tests.

The tests are carried out by our own specifically trained and certified specialist personnel or accredited testing institutes.

Our testing equipment is continuously monitored and calibrated as part of our quality management system.

On request, we issue test certificates or test reports for your deliveries.

High-pressure and ultrasonic cleaning

A clean matter. Finished parts without annoying chips, cleaned free of particles or grease and cleanly packaged allow the entire manufacturing process to be shortened. Your parts go directly to final assembly or surface coating without further treatment.

Know-how

Our high-pressure washing systems are suitable for the professional cleaning of medium to large parts.

Ultrasonic cleaning is suitable for smaller parts. This type of cleaning is important, for example, as a pre-treatment before coating.

Our large machine park includes:

High pressure washing machines: The modern system has an automatic washing system with a rotating system, safety technology and a nozzle block with adjustable nozzles. Various programmes optimally cover customer requirements.

Ultrasonic cleaning: We use this process for cleaning precision parts and welding components for the life sciences, semiconductor or food industry.

WORKING RANGE

- Washing machines: Xmax: 1'600 Ymax: 1'600 Zmax: 1'300

- High pressure: 160 bar max

- Maximum particle size: < 300μm

- Table load: 800 kg max

- Separate circuits for rinsing and washing process.

- Ultrasonic cleaning: Xmax: 400 Ymax: 300 (larger dimensions on request).

DO YOU HAVE ANY QUESTIONS ABOUT OUR OFFER? WE WILL BE HAPPY TO ANSWER.

Contact persons

Sales

SALES- FRENCH, ITALIAN AND SPANISH SPEAKING REGIONS & COUNTRIES

Management