Sheet metal working

Modern and efficient sheet metal processing from A to Z - all from one source!

We support you in the design and manufacture of your sheet metal parts and welded assemblies as individual or series parts. Benefit from our extensive experience and the wide range of rational and modern manufacturing processes.

Choose one of our competences and learn more:

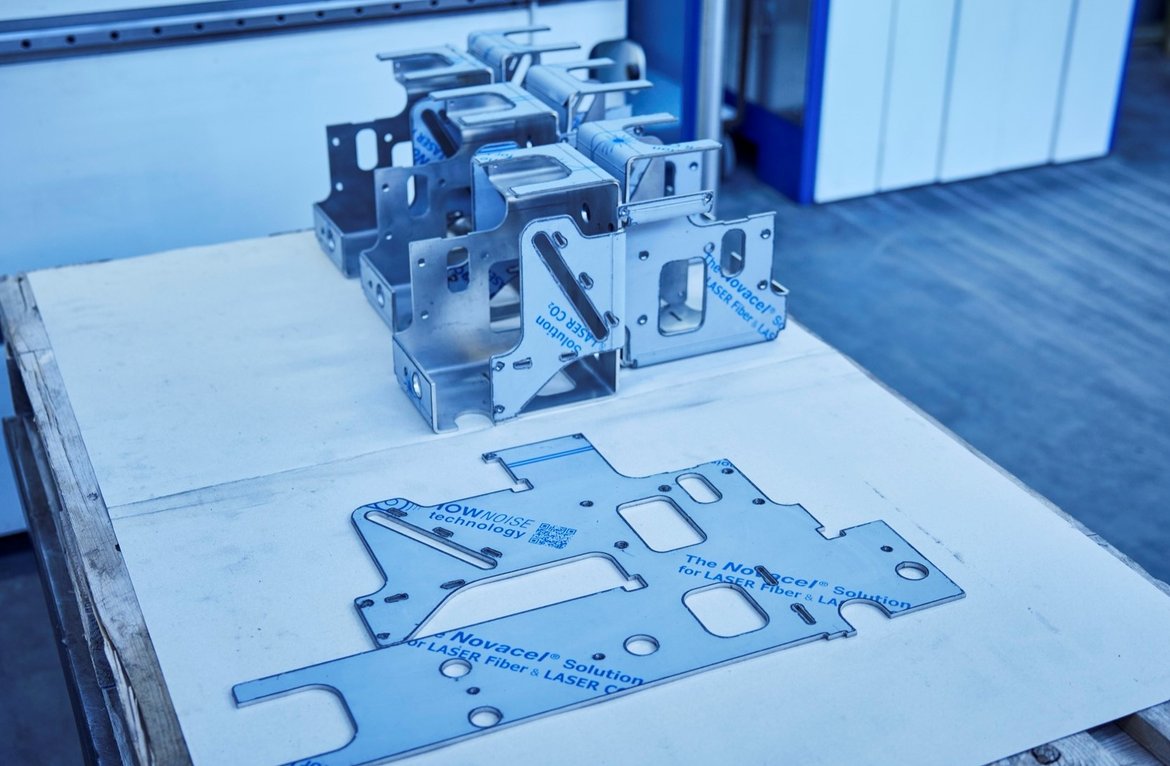

CNC laser cutting / CNC punching-laser cutting combined

Laser cutting in combination with punching combines the advantages of both techniques. Particularly demanding sheet metal products can be ideally produced in combination with lasers and punching.

Know-how

With the latest and fully automated technology (Trumpf Trumatic 7000), complete processing can be offered. (Punching, lasering, thread forming, embossing, countersinking, edging, gilling, beading). Thanks to unmanned production, we can offer you a perfect price/performance ratio.

WORKING RANGE

- Automated CNC punching laser systems up to a sheet size of 1250x2500mm

- Automated laser systems up to sheet size 1500x3000mm

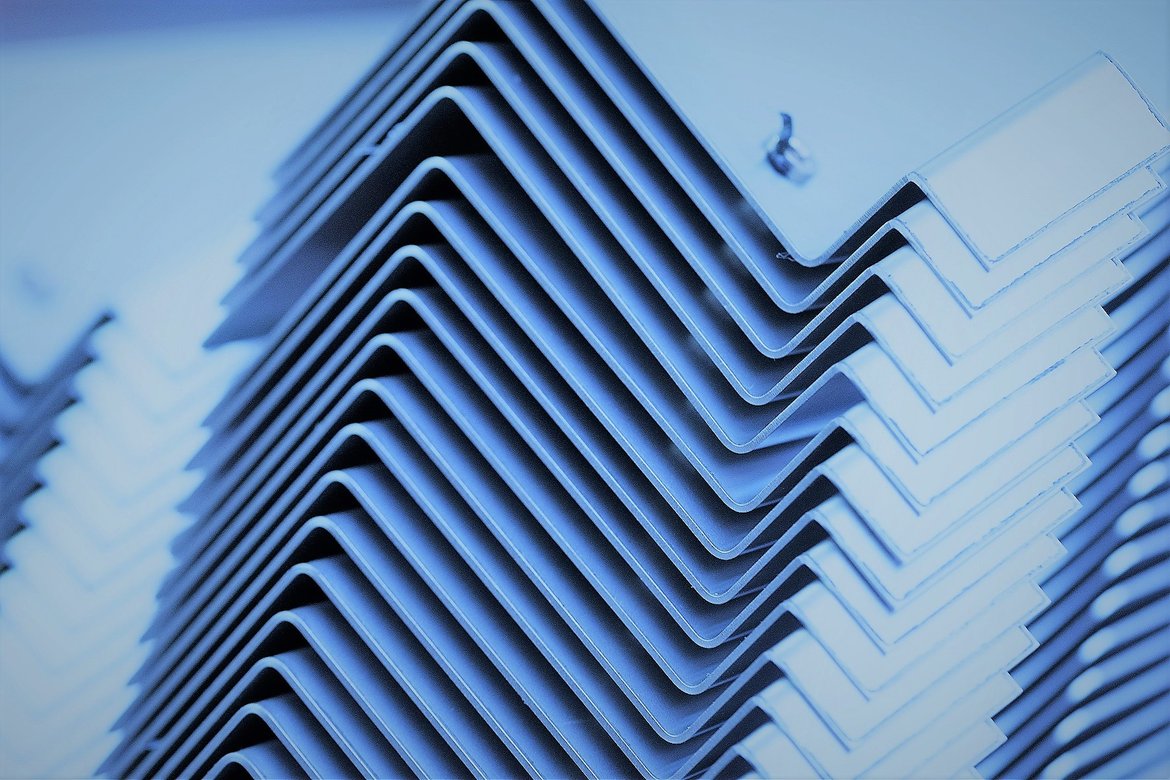

Bending / Forming

The execution of your demanding bending work with the highest precision is guaranteed by our know-how on technically advanced CNC bending machines.

Know-how

Our work preparation department makes the constantly updated programmes available online. The operator at the press brake can concentrate fully on his work. Production thus gains in quality, safety and time. Innovation, quality and precision are the guiding principles of our employees.

WORKING RANGE

- Bending lengths up to 3.0 m

- Sheet thicknesses up to 20 mm

- Pressing force up to 230 to

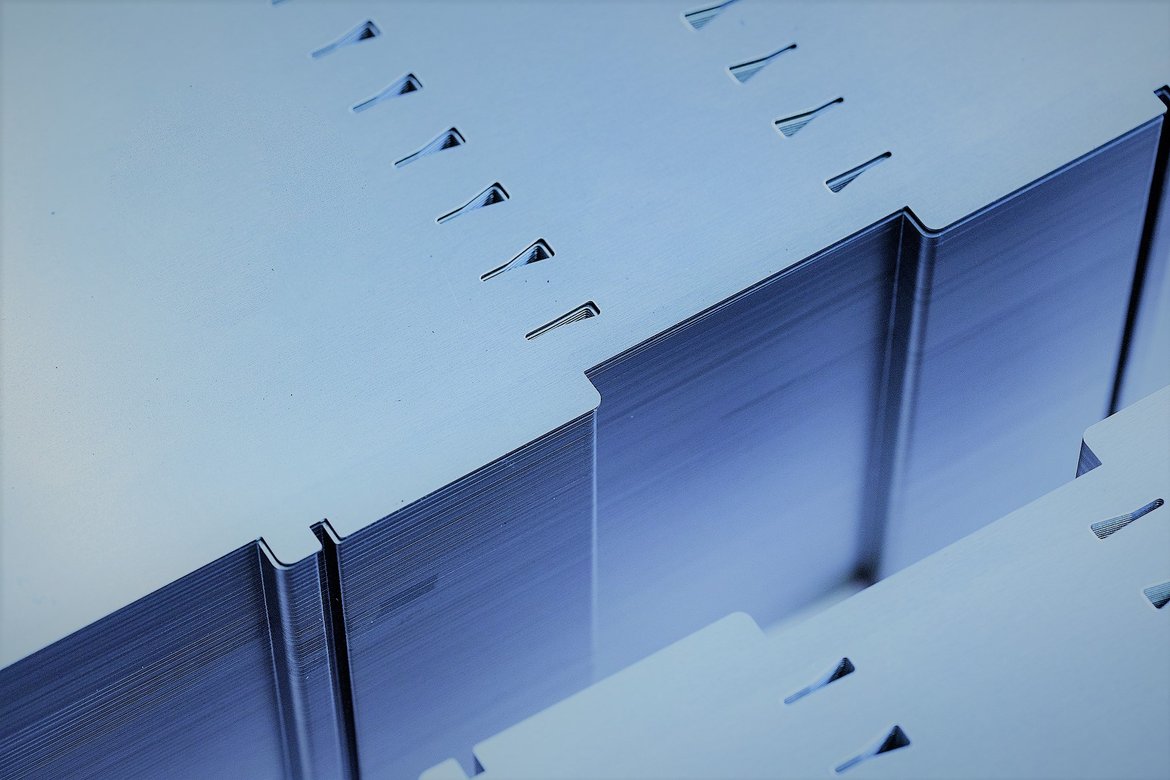

Welding, clinching, gluing and riveting

Are you looking for a new joining technique? We will find the solution for you. In addition to standard TIG/MIG/MAG welding, we have a high level of expertise in spot and stud welding, bonding, clinching (toxing), press-fitting or riveting.

Know-how

Welding is often the optimal joining technique. But clinching has also been gaining ground for longer and longer. With the help of a simple, symmetrical rivet as a joining aid, a clinch connection "with core" is produced. Without cutting the material, a higher strength is achieved in direct comparison to a conventional self-piercing rivet. The use of the TOX ClinchRivet in the crumple zones of passenger cars confirms the performance of this versatile sheet metal connection.

WORKING RANGE

- TIG/MIG/MAG welding

- Spot and stud welding

- Clinching

- Riveting

- Gluing

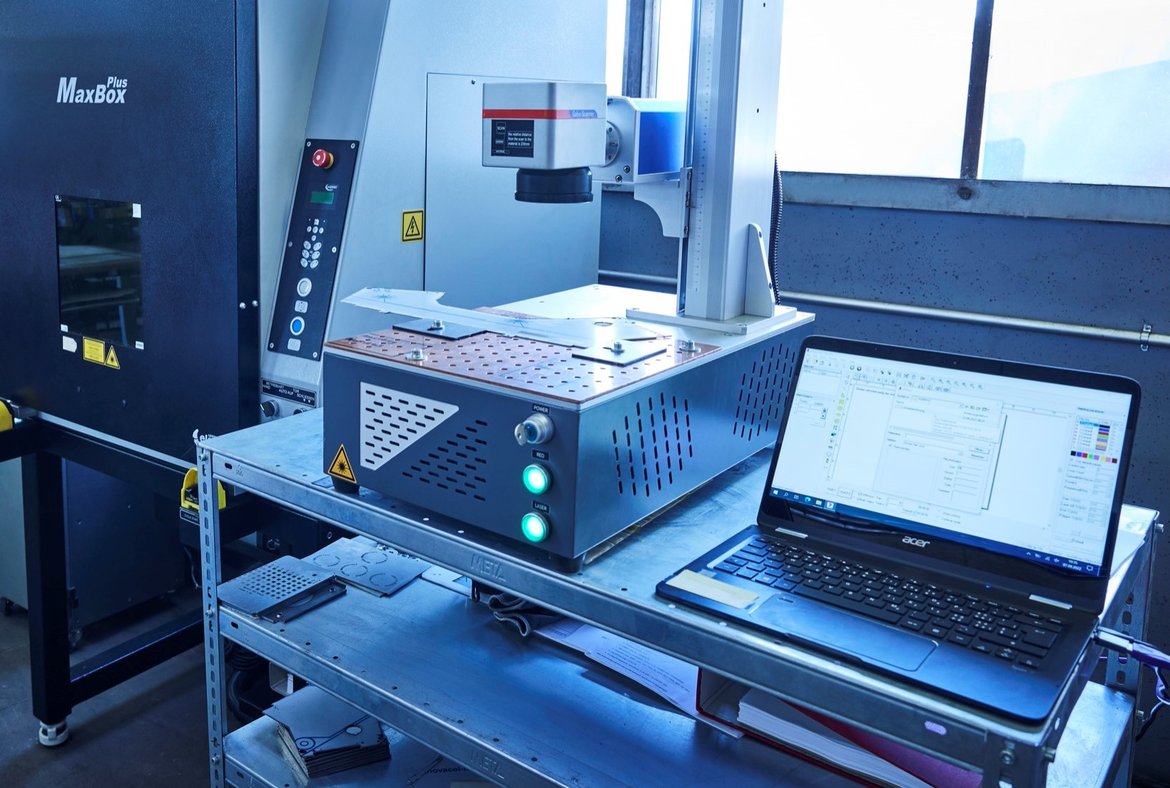

LASER ENGRAVING

"Look at me and I'll tell you what you are". Laser engraving is one of our many marking options. Such direct and professional marking saves time and reduces errors.

Know-how

Professional and durable marking is a prerequisite for simple component identification and full traceability. For a minimisation of administrative tasks and full transparency.

Each of our production sites has modern and variously programmable laser engraving machines. In accordance with our customers' requirements, the marking is carried out. Combinations of numbers and letters up to logos and graphics are possible.

Our large machine park includes various programmable CNC laser engraving machines.

Input: customer specifications in DXF format

Coating / Surface treatments

We coat your components and assemblies in all common surface treatment processes: wet painting, KTL coatings, hot-dip galvanising, electroplating, chrome-plating, anodising and so on. For this, we work together with selected and reliable external partners.

Learn more: Surface treatment competenceDO YOU HAVE ANY QUESTIONS ABOUT OUR OFFER? WE WILL BE HAPPY TO ANSWER.

Contact Persons

Sales

Oscar Ortiz

CNC machining / welding technology

Components & assemblies

Pascal Sequin

CNC machining / welding technology

Components & assemblies

Ines Lachetta

Sheet metal processing

Laser cutting-punching-bending-welding-assembling

Site Manager

Management