Welding technology for the highest demands

We cover a wide range of manual and automated welding technologies - just right and optimised for your individual assemblies and systems.

Our processes and welding methods are certified according to ISO 3834-2, EN 15085-2 CL1, EN1090-2 and PED 2014/68/EU and cover a wide range of applications, be it in railway technology, pressure equipment construction or for load-bearing welded constructions.

Choose one of our competences and learn more:

MIG / MAG / TIG / MMA-Welding

Certified welding technology for the highest demands. Thanks to our certified specialists and welding processes, the specifications of our customers in a wide range of industries can be fully met.

Know-how

We weld a wide range of materials, such as general structural steels, high-temperature and fine-grain steels, chrome-nickel materials, aluminium alloys, nickel-based alloys as well as mixed joints using the MIG, MAG, TIG, MMA processes.

WELDING APPROVALS ACCORDING TO

- EN 15085-2 CL-1 for welding of rail vehicles and vehicle parts

- PED 2014/68/EU for welding of pressure equipment

- EN 1090-2 for welding of steel structures

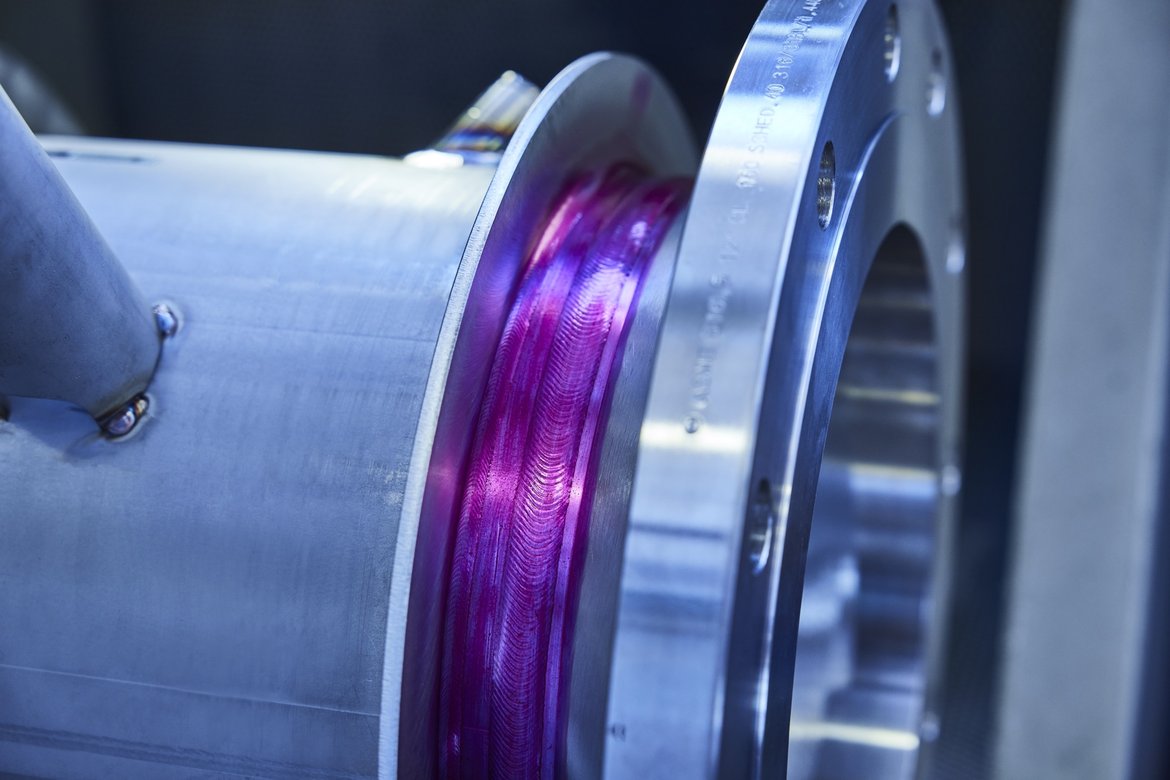

Automated and mechanised welding

Thanks to mechanised and automated welding processes, we achieve maximum, repetitive process reliability and thus consistently the highest quality and safety.

Know-how

For larger quantities (series) or long welding seams, we can carry out welding work efficiently and with consistent quality by using welding robots, automatic circular and longitudinal welding machines as well as product-specific welding machines.

The advantages of mechanised and automated welding processes are impressive. We can perform the joining tasks much faster, at a consistently high quality level and cost-efficiently.

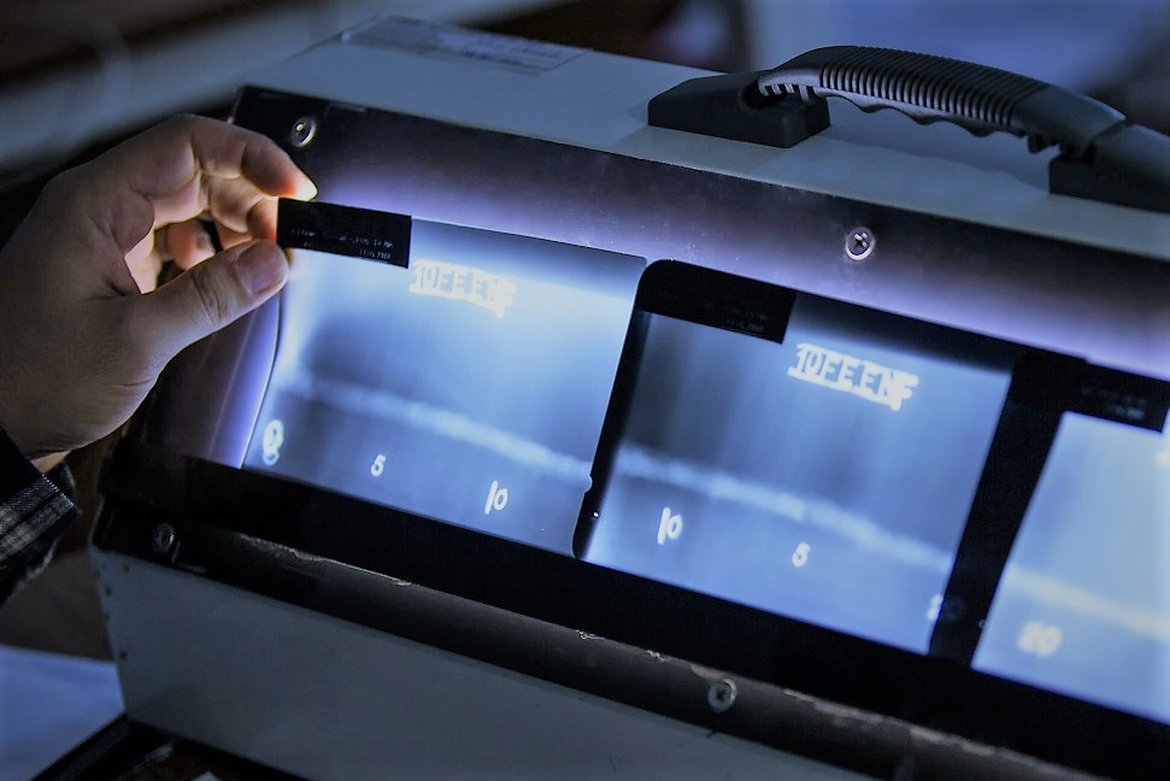

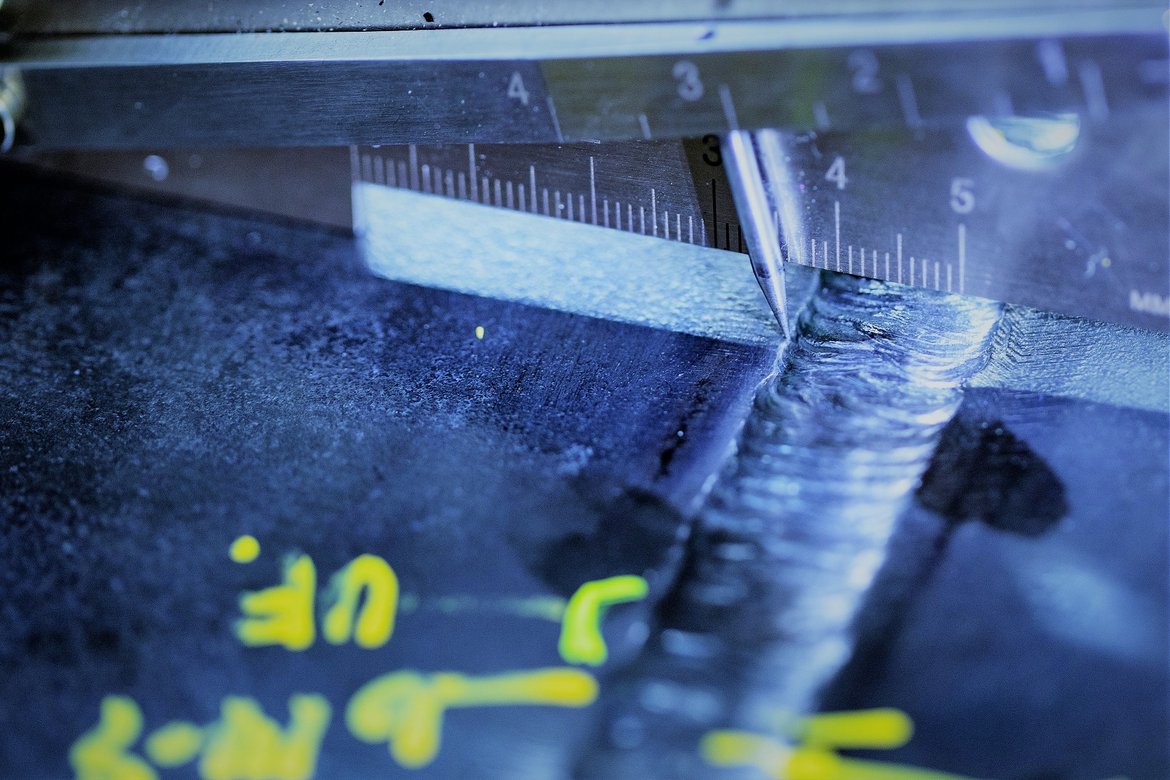

Test procedures

The execution of the prescribed test procedures such as X-ray, ultrasound or dye penetration testing as well as the preparation of the verification documents are part of our standard.

COMPETENCE

All tests are carried out by our own specifically trained and certified personnel or by accredited testing institutes.

NON-DESTRUCTIVE TESTING METHODS

- Visual inspections

- Dye penetrant testing

- X-ray testing

- Test bench for pressure tests (high pressure)

- Material identification testing

Certifications & Approvals

Through internal and external monitoring and certification, we ensure compliance with international norms and industry standards.

APPROVALS AND CERTIFIED MANUFACTURING PROCESSES:

- Management system according to EN ISO 9001:2015 as well as EN ISO 3834-2 for welding requirements.

- Welding approvals in accordance with EN 15085-2 CL-1 for the welding of rail vehicles and vehicle component ends

- According to the regulations of the European Pressure Equipment Directive 2014/68/EU Module H Cat. /III/IV; AD-2000 HP0/ TRD 201

- Qualified welding procedures according to EN ISO 15614-1; ASME IX; AD-2000. Qualified personnel according to ISO 14731, welding personnel according to EN 287-1 / ISO 9606, EN 1418.

DO YOU HAVE ANY QUESTIONS ABOUT OUR OFFER? WE WILL BE HAPPY TO ANSWER.

Contact Persons

Sales

Oscar Ortiz

CNC machining / welding technology

Components & assemblies

Pascal Sequin

CNC machining / welding technology

Components & assemblies

Ines Lachetta

Sheet metal processing

Laser cutting-punching-bending-welding-assembling

Site Manager

Management